| 413-01 Instrumentation, Message Center and Warning Chimes

|

2013 - 2014 Fusion

|

| Diagnosis and Testing

|

Procedure revision date:

07/10/2013

|

Instrumentation, Message Center and Warning Chimes

DTC Chart: Instrument Panel Cluster (IPC)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Chart -

|

DTC

|

Description

|

Action

|

|

P0460:11

|

Fuel Level Sensor "A" Circuit: Circuit Short To Ground

|

For single sender L-shaped fuel tank,

GO to Pinpoint Test C

For dual sender saddle-type fuel tank,

GO to Pinpoint Test D

|

|

P0460:13

|

Fuel Level Sensor "A" Circuit: Circuit Open

|

For single sender L-shaped fuel tank,

GO to Pinpoint Test C

For dual sender saddle-type fuel tank,

GO to Pinpoint Test D

|

|

P1243:06

|

Second Fuel Pump Fault or Ground Fault: Algorithm Based Failure

|

GO to Pinpoint Test D

|

|

P1346:11

|

Fuel Level Sensor "B" Circuit: Circuit Short To Ground

|

GO to Pinpoint Test D

|

|

P1346:13

|

Fuel Level Sensor "B" Circuit: Circuit Open

|

GO to Pinpoint Test D

|

|

P1534:01

|

Restraint Deployment Indicator Circuit: General Electrical Failure

|

INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

Diagnose all

Diagnostic Trouble Codes (DTCs).

REFER to:

Airbag Supplemental Restraint System (SRS)

(501-20B Supplemental Restraint System, Diagnosis and Testing).

|

|

P1706:00

|

High Vehicle Speed Observed in Park: No Sub Type Information

|

GO to Pinpoint Test Z

|

|

U0100:00

|

Lost Communication With ECM/PCM "A": No Sub Type Information

|

GO to Pinpoint Test BG

|

|

U0101:00

|

Lost Communication with TCM: No Sub Type Information

|

GO to Pinpoint Test BH

|

|

U0104:00

|

Lost Communication With Cruise Control Module: No Sub Type Information

|

GO to Pinpoint Test BI

|

|

U0121:00

|

Lost Communication With Anti-Lock Brake System (ABS) Control Module: No Sub Type Information

|

GO to Pinpoint Test BJ

|

|

U0121:87

|

Lost Communication With Anti-Lock Brake System (ABS) Control Module: Missing Message

|

GO to Pinpoint Test BJ

|

|

U0131:00

|

Lost Communication With Power Steering Control Module: No Sub Type Information

|

GO to Pinpoint Test BK

|

|

U0140:00

|

Lost Communication With Body Control Module: No Sub Type Information

|

GO to Pinpoint Test BL

|

|

U0140:87

|

Lost Communication With Body Control Module: Missing Message

|

GO to Pinpoint Test BL

|

|

U0146:00

|

Lost Communication With Gateway "A": No Sub Type Information

|

GO to Pinpoint Test BM

|

|

U0151:00

|

Lost Communication With Restraints Control Module: No Sub Type Information

|

GO to Pinpoint Test BN

|

|

U0151:87

|

Lost Communication With Restraints Control Module: Missing Message

|

GO to Pinpoint Test BN

|

|

U0154:87

|

Lost Communication With Restraints Occupant Classification System Module: Missing Message

|

GO to Pinpoint Test BO

|

|

U0159:00

|

Lost Communication With Parking Assist Control Module "A": No Sub Type Information

|

GO to Pinpoint Test BP

|

|

U016A:00

|

Lost Communication With Global Positioning System Module: No Sub Type Information

|

GO to Pinpoint Test BQ

|

|

U0184:00

|

Lost Communication With Radio: No Sub Type Information

|

GO to Pinpoint Test BR

|

|

U0199:00

|

Lost Communication With "Door Control Module A": No Sub Type Information

|

GO to Pinpoint Test BS

|

|

U0212:00

|

Lost Communication With Steering Column Control Module: No Sub Type Information

|

GO to Pinpoint Test BT

|

|

U0232:00

|

Lost Communication With Side Obstacle Detection Control Module - Left: No Sub Type Information

|

GO to Pinpoint Test BU

|

|

U0233:00

|

Lost Communication With Side Obstacle Detection Control Module - Right: No Sub Type Information

|

GO to Pinpoint Test BU

|

|

U023A:00

|

Lost Communication With Image Processing Module A: No Sub Type Information

|

GO to Pinpoint Test BV

|

|

U0241:00

|

Lost Communication With Headlamp Control Module "A": No Sub Type Information

|

GO to Pinpoint Test BV

|

|

U0401:00

|

Invalid Data Received from ECM/PCM A: No Sub Type Information

|

This

sets when the

receives invalid network data for the speedometer, temperature or odometer data from the

. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network. Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual.

Refer to the appropriate section in Group 303 for the procedure.

|

|

U0401:81

|

Invalid Data Received from ECM/PCM A: Invalid Serial Data Received

|

This

sets when the

receives invalid network data for the speedometer, temperature or odometer data from the

. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network. Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual.

Refer to the appropriate section in Group 303 for the procedure.

|

|

U0401:82

|

Invalid Data Received from ECM/PCM A: Alive/Sequence Counter Incorrect/Not Updated

|

GO to Pinpoint Test BG

|

|

U0405:56

|

Invalid Data Received From Cruise Control Module: Invalid/Incompatible Configuration

|

This

sets when the

receives invalid network data for adaptive cruise control from the Cruise Control Module (C-CM). CHECK the vehicle service

history for recent service actions related to this module. This

sets due to incomplete or incorrect Programmable Module Installation (PMI) procedures. If there have been recent service

actions with this module, REPEAT the Programmable Module Installation (PMI) procedure as directed by the scan tool. If there

have been no recent service actions, INSTALL a new module to correct the failure to retain configuration data.

|

|

U0415:56

|

Invalid Data Received From Anti-Lock Brake System (ABS) Control Module: Invalid/Incompatible Configuration

|

This

sets when the

receives invalid network data for adaptive cruise control from the Cruise Control Module (C-CM). CHECK the vehicle service

history for recent service actions related to this module. This

sets due to incomplete or incorrect Programmable Module Installation (PMI) procedures. If there have been recent service

actions with this module, REPEAT the Programmable Module Installation (PMI) procedure as directed by the scan tool. If there

have been no recent service actions, INSTALL a new module to correct the failure to retain configuration data.

|

|

U0420:82

|

Invalid Data Received From Power Steering Control Module: Alive/Sequence Counter Incorrect/Not Updated

|

GO to Pinpoint Test BK

|

|

U0422:00

|

Invalid Data Received From Body Control Module: No Sub Type Information

|

This

sets when the

receives invalid network

data from the

. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

|

U0424:00

|

Invalid Data Received From HVAC Control Module: No Sub Type Information

|

This

sets when the

receives invalid network data for the outside air temperature display from the

module. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network. Refer to the appropriate section in Group 303 for the procedure.

|

|

U0424:81

|

Invalid Data Received From HVAC Control Module: Invalid Serial Data Received

|

This

sets when the

receives invalid network data for the outside air temperature display from the

module. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network. Refer to the appropriate section in Group 303 for the procedure.

|

|

U0424:82

|

Invalid Data Received From HVAC Control Module: Alive/Sequence Counter Incorrect/Not Updated

|

GO to Pinpoint Test BW

|

|

U0452:81

|

Invalid Data Received From Restraints Control Module: Invalid Serial Data Received

|

This

sets when the

receives invalid network data from the

due to incorrect Belt-Minder® configuration in the

. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network.

REFER to:

Airbag Supplemental Restraint System (SRS)

(501-20B Supplemental Restraint System, Diagnosis and Testing).

|

|

U046B:86

|

Invalid Data Received From Global Positioning System Module: Signal Invalid

|

This

sets when the

receives invalid network data from the

. RETRIEVE and REPAIR all non-network Diagnostic Trouble Codes (DTCs) in the

and other modules on the network. Refer to the appropriate section in Group 415 for the procedure.

|

|

U0533:56

|

Invalid Data Received From Side Obstacle Detection Control Module-Left: Invalid/Incompatible Configuration

|

This

sets when the

receives invalid network data from the

. CHECK the vehicle service history for recent service actions related to this module. This

sets due to incomplete or incorrect Programmable Module Installation (PMI) procedures. If there have been recent service

actions with this module, REPEAT the Programmable Module Installation (PMI) procedure as directed by the scan tool. If there

have been no recent service actions, INSTALL a new module to correct the failure to retain configuration data.

|

|

U0533:82

|

Invalid Data Received From Side Obstacle Detection Control Module-Left: Alive/Sequence Counter Incorrect/Not Updated

|

GO to Pinpoint Test BU

|

|

U0534:56

|

Invalid Data Received From Side Obstacle Detection Control Module-Right: Invalid/Incompatible Configuration

|

This

sets when the

receives invalid network data from the

. CHECK the vehicle service history for recent service actions related to this module. This

sets due to incomplete or incorrect Programmable Module Installation (PMI) procedures. If there have been recent service

actions with this module, REPEAT the Programmable Module Installation (PMI) procedure as directed by the scan tool. If there

have been no recent service actions, INSTALL a new module to correct the failure to retain configuration data.

|

|

U0534:82

|

Invalid Data Received From Side Obstacle Detection Control Module-Right: Alive/Sequence Counter Incorrect/Not Updated

|

GO to Pinpoint Test BU

|

|

U2100:00

|

Initial Configuration Not Complete: No Sub Type Information

|

CHECK the vehicle service history for recent service actions related to this module. This

sets due to incomplete or incorrect Programmable Module Installation (PMI) procedures. If there have been recent service

actions with this module, REPEAT the Programmable Module Installation (PMI) procedure as directed by the scan tool.

REFER to:

Module Configuration - System Operation and Component Description

(418-01 Module Configuration, Description and Operation).

If there have been no recent service actions, INSTALL a new module to correct the failure to retain configuration data.

|

|

U3000:04

|

Control Module: System Internal Failure

|

CLEAR the Diagnostic Trouble Codes (DTCs). REPEAT the self-test. If

U3000:04 is retrieved again, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

U3000:41

|

Control Module: General Checksum Failure

|

CLEAR the Diagnostic Trouble Codes (DTCs). REPEAT the self-test. If

U3000:41 is retrieved again, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

U3000:42

|

Control Module: General Memory Failure

|

CLEAR the Diagnostic Trouble Codes (DTCs). REPEAT the self-test. If

U3000:42 is retrieved again, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

U3000:43

|

Control Module: Special Memory Failure

|

CLEAR the Diagnostic Trouble Codes (DTCs). REPEAT the self-test. If

U3000:43 is retrieved again, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

U3000:44

|

Control Module: Data Memory Failure

|

CLEAR the Diagnostic Trouble Codes (DTCs). REPEAT the self-test. If

U3000:44 is retrieved again, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

U3000:46

|

Control Module: Calibration/Parameter Memory Failure

|

CLEAR the Diagnostic Trouble Codes (DTCs). REPEAT the self-test. If

U3000:46 is retrieved again, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

U3000:54

|

Control Module: Missing Calibration

|

CHECK the vehicle service history for recent service actions related to this module. This

sets due to incomplete or incorrect calibration files. If there have been recent service actions with this module, REFLASH

the

. If there have been no recent service actions, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

U3003:16

|

Battery Voltage: Circuit Voltage Below Threshold

|

GO to Pinpoint Test BX

|

|

U3003:17

|

Battery Voltage: Circuit Voltage Above Threshold

|

GO to Pinpoint Test BY

|

|

U300A:64

|

Ignition Switch: Signal Plausibility Failure

|

U300A:64 sets in continuous memory when the

detects a messaged START input for 15 seconds or longer. Once the fault condition is detected, the

operates with limited functionality for 15 seconds then returns to full functionality. Diagnose the ignition start circuit

to the

.

REFER to:

Steering Wheel and Column Electrical Components

(211-05 Steering Wheel and Column Electrical Components, Diagnosis and Testing).

|

DTC Chart: Body Control Module (BCM)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Chart -

DTC Chart: Powertrain Control Module (PCM)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Chart -

|

DTC

|

Description

|

Action

|

|

P0460

|

Fuel Level Sensor "A" Circuit

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual, for single sender L-shaped fuel tank,

GO to Pinpoint Test C

For dual sender saddle-type fuel tank,

GO to Pinpoint Test D

|

|

P0461

|

Fuel Level Sensor "A" Circuit Range/Performance

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual, for single sender L-shaped fuel tank,

GO to Pinpoint Test C

For dual sender saddle-type fuel tank,

GO to Pinpoint Test D

|

|

P0462

|

Fuel Level Sensor "A" Circuit Low

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual, for single sender L-shaped fuel tank,

GO to Pinpoint Test C

For dual sender saddle-type fuel tank,

GO to Pinpoint Test D

|

|

P0463

|

Fuel Level Sensor "A" Circuit High

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual, for single sender L-shaped fuel tank,

GO to Pinpoint Test C

For dual sender saddle-type fuel tank,

GO to Pinpoint Test D

|

|

P2065

|

Fuel Level Sensor "B" Circuit

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual,

GO to Pinpoint Test D

|

|

P2066

|

Fuel Level Sensor "B" Circuit Range/Performance

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual,

GO to Pinpoint Test D

|

|

P2067

|

Fuel Level Sensor "B" Circuit Low

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual,

GO to Pinpoint Test D

|

|

P2068

|

Fuel Level Sensor "B" Circuit High

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual,

GO to Pinpoint Test D

|

|

P25B0

|

Fuel Level Sensor "A" Stuck

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual, for single sender L-shaped fuel tank,

GO to Pinpoint Test C

For dual sender saddle-type fuel tank,

GO to Pinpoint Test D

|

|

P25B1

|

Fuel Level Sensor "B" Stuck

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual,

GO to Pinpoint Test D

|

|

P25B2

|

Fuel Level Sensor "A" or "B" Stuck

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual. If sent here from the

manual, for single sender L-shaped fuel tank,

GO to Pinpoint Test C

For dual sender saddle-type fuel tank,

GO to Pinpoint Test D

|

|

All other DTCs

|

-

|

Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual.

Refer to the appropriate section in Group 303 for the procedure.

|

DTC Chart: Steering Column Control Module (SCCM)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Chart -

Symptom Chart(s)

Symptom Chart: Instrument Panel Cluster (IPC)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Symptom Chart

|

Condition

|

Possible Sources

|

Actions

|

|

A module does not respond to the scan tool

|

-

Fuse

-

Wiring, terminals or connectors

-

Communication concern

-

Module

|

REFER to:

Communications Network

(418-00 Module Communications Network, Diagnosis and Testing).

|

|

The

is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test A

|

|

Multiple gauges, indicators, message center indicators, warnings and chimes are inoperative or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test A

|

|

A virtual gauge (

, tachometer or temperature), is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test B

|

|

Incorrect fuel gauge indication - single sender l-shaped fuel tank

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test C

|

|

Incorrect fuel gauge indication - dual sender saddle-type fuel tank

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test D

|

|

The speedometer is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test E

|

|

Incorrect speedometer indication

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test F

|

|

The odometer is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test G

|

|

The analog tachometer is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test H

|

|

Incorrect analog tachometer indication

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test I

|

|

The analog temperature gauge is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test J

|

|

Incorrect analog temperature gauge indication

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test K

|

|

The

warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test L

|

|

The airbag warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test M

|

|

The auto stop-start indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test N

|

|

The brake warning indicator is never on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test O

|

|

The brake warning indicator is always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test P

|

|

The charging system warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test Q

|

|

The door ajar warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test R

|

|

The electric park brake indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test W

|

|

The

-

turn signal, fog lamp or high beam indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test S

|

|

The low fuel warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test T

|

|

The low oil pressure warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test U

|

|

The

is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test V

|

|

The lights on indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test X

|

|

The powertrain malfunction (wrench) indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test Y

|

|

The PRNDL indicator is never on or never displays P

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test Z

|

|

The safety belt warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AA

|

|

The stability-traction control indicator (sliding car icon) is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AB

|

|

The stability-traction control disabled indicator (sliding car OFF icon) is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AC

|

|

The

warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AD

|

Symptom Chart: Information And Message Center

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Symptom Chart

|

Condition

|

Possible Sources

|

Actions

|

|

The message center is not operating correctly

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AE

|

|

The

or

message center display is blank

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test A

|

|

A virtual display is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test B

|

|

The compass is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AF

|

|

The outside air temperature display is inoperative or incorrect

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AG

|

|

The auto stop-start message center indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AH

|

|

The Blind Spot Information System (BLIS) off message center indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AI

|

|

The charging system message center warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AJ

|

|

The cruise control message center indicator is never on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AK

|

|

The door ajar message center warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AL

|

|

The engine over-temperature message center warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AM

|

|

The lane departure on message center indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AN

|

|

The low fuel message center warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AO

|

|

The low oil pressure message center warning indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AP

|

|

The powertrain malfunction (wrench) message center indicator is never or always on

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AQ

|

|

A brake warning (brake fluid level low, parking brake applied or brake system malfunction) message is never or always on

|

-

Message center concern

-

Brake warning indication concern

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly and the brake warning indicator is never on,

GO to Pinpoint Test O

-

If the driver door ajar message functions correctly and the brake warning indicator is always on,

GO to Pinpoint Test P

|

|

The charging system warning message is never or always on

|

-

Message center concern

-

Charging system message center indication concern

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly,

GO to Pinpoint Test AJ

|

|

The check fuel fill inlet message is always displayed

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AR

|

|

The engine oil change message is never displayed

|

-

Message center concern

-

The

has not reached the programmed mileage/time based on the criteria required to display the message.

|

NOTE:

Using the system check in the message center, verify that the oil life is between 1 and 5% for the ENGINE OIL CHANGE SOON

message or at 0% for the OIL CHANGE REQUIRED message.

-

OPEN then CLOSE the driver door and VERIFY the DRIVER DOOR AJAR message functions correctly.

-

If the DRIVER DOOR AJAR message does not function correctly,

GO to Pinpoint Test AL

-

If the DRIVER DOOR AJAR message functions correctly with the oil life between 0-5%, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

-

If the DRIVER DOOR AJAR message functions correctly with the oil life

not

at the specified value, INFORM the customer how the message center functions and how the oil life messages are set.

|

|

The engine oil change message is always displayed

|

The oil life needs reset

|

RESET the oil life. REFER to the Owner's Literature.

|

|

A MyKey® menu is not available or incorrect

|

-

MyKey® programmed key in use

-

Number of keys set to unlimited mode

-

Non-Ford approved remote start system installed

|

NOTE:

MyKey® may not be compatible with non-Ford approved remote start systems.

-

REFER to the Owner's Literature.

|

|

A passive key status (no key detected, key inside vehicle, key not inside vehicle or place key in keyholder) message is never

or always displayed (push button start)

|

-

Message center concern

-

Passive key concern

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly,

REFER to:

Locks, Latches and Entry Systems

(501-14 Handles, Locks, Latches and Entry Systems, Diagnosis and Testing).

|

|

The perimeter alarm message is always displayed

|

-

Message center concern

-

Perimeter alarm concern

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly,

REFER to:

Perimeter Anti-Theft Alarm

(419-01A Perimeter Anti-Theft Alarm, Diagnosis and Testing).

|

|

The service AdvanceTrac® malfunction warning is never or always displayed

|

-

Message center concern

-

Stability-traction control concern

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly, DIAGNOSE the stability-traction control warning indicator.

GO to Pinpoint Test AB

|

|

The shift to park display is never or always on

|

Refer to the Pinpoint Test

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly, DIAGNOSE the PRNDL.

GO to Pinpoint Test Z

|

|

The stability-traction control malfunction warning is never or always on

|

-

Message center concern

-

Stability-traction control indication concern

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly,

GO to Pinpoint Test AB

|

|

The stability-traction control disabled warning is never on

|

-

Message center concern

-

Stability-traction control disable indication concern

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly,

GO to Pinpoint Test AB

|

|

A steering malfunction message is always on

|

-

Message center concern

-

system concern

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly, DIAGNOSE the

.

REFER to:

Power Steering

(211-02 Power Steering, Diagnosis and Testing).

|

|

The tire training complete message is never on

|

sensor training incomplete

|

NOTE:

This message only appears during the

sensor training procedure.

|

|

A

malfunction message is never or always on

|

-

Message center concern

-

warning indication concern

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly,

GO to Pinpoint Test AD

|

|

A tire training message (train left front, right front, left rear or right rear tire) message is never on

|

-

warning indicator concern

-

sensor training concern

|

NOTE:

These messages only appear during the

sensor training procedure.

|

|

The tires not trained message is always on

|

sensor training concern

|

|

|

The transport mode message is always on

|

Vehicle is in transport mode

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly, DISABLE the transport mode and PLACE the vehicle in normal operation

mode.

REFER to:

Transport Mode Deactivation

(419-10 Multifunction Electronic Modules, General Procedures).

|

|

A vehicle starting/ignition status (press brake to start or switch ignition off press power) message is always on

|

-

Message center concern

-

Push button start concern

|

-

OPEN then CLOSE the driver door and VERIFY the driver door ajar message displays correctly with the door open and closed.

-

If the driver door ajar message does not function correctly,

GO to Pinpoint Test AL

-

If the driver door ajar message functions correctly,

REFER to:

Steering Wheel and Column Electrical Components

(211-05 Steering Wheel and Column Electrical Components, Diagnosis and Testing).

|

Symptom Chart: Warning Chimes

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Symptom Chart

|

Condition

|

Possible Sources

|

Actions

|

|

All the chimes are inoperative

|

|

GO to Pinpoint Test A

|

|

The active park assist chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AS

|

|

The adaptive cruise control warning chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AT

|

|

The airbag secondary warning chime is inoperative

|

|

-

Using a diagnostic scan tool, PERFORM the

self-test.

-

If

P1534:01 is present, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

-

If

P1534:01 is

not

present, the system is operating correctly. The airbag secondary warning chime sounds only when a fault in the airbag warning

indicator is present and

P1534:01 is recorded.

|

|

The airbag secondary warning chime has activated

|

|

INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

The Belt-Minder® feature is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test BE

|

|

The Belt-Minder® cannot be deactivated

|

MyKey® programmed key in use

|

The system is operating correctly. Use an administrator key to disable the Belt-Minder®.

|

|

The Blind Spot Information System (BLIS)/Cross Traffic Alert (CTA) warning chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AU

|

|

The chime always sounds

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AV

|

|

The chime only sounds from the

|

-

Communication concern

-

concern

-

Audio system concern

|

-

Using a diagnostic scan tool, perform the

self-test.

-

If any Diagnostic Trouble Codes (DTCs) are present, REFER to

Chart:

in this section

-

If no Diagnostic Trouble Codes (DTCs), DIAGNOSE the audio system. Refer to the appropriate section in Group 415 for the procedure.

|

|

The door ajar warning chime is inoperative

|

-

Door ajar indication concern

-

|

-

With the ignition OFF, the headlamps in the PARKING LAMPS position and the doors closed, OPEN the driver door and VERIFY the

headlamps on warning chime sounds.

-

If the headlamps on chime sounds,

GO to Pinpoint Test AL

-

If the headlamps on chime does not sound, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

The forward collision warning chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AW

|

|

The headlamps on warning chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AX

|

|

The ignition-engine on warning chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AY

|

|

The key-in-ignition warning chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AZ

|

|

The lane keeping aid warning chime is inoperative

|

Refer to the Pinpoint Test

|

NOTE:

The lane keeping aid warning chime only sounds to alert the driver that they have their hands off the steering wheel. Normal

alerting is done through steering wheel vibrations, which cannot be felt when the driver's hands are not on the steering wheel.

GO to Pinpoint Test BA

|

|

The lane keeping aid warning chime sounds with the hands on the steering wheel

|

Road conditions

|

Certain road conditions could lead to false activation of the chime.

REFER to:

Lane Departure Warning - System Operation and Component Description

(419-07 Lane Departure Warning, Description and Operation).

|

|

The memory-stored feedback warning chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test BB

|

|

The message center warning chime is inoperative

|

|

-

With all the doors closed and the ignition OFF, PLACE the ignition ON. Once the

has completed the prove-out, OPEN the driver door and VERIFY the message center displays the door ajar message center indicator

and the chime sounds once.

-

If the chime sounds, the system is operating correctly. The message center warning chime only sounds when a new warning is

displayed in the message center.

-

If the door ajar message does not display,

GO to Pinpoint Test AL

-

If the door ajar message displays and the chime does not sound, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

The parking aid chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test AS

|

|

The parking brake warning chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test BC

|

|

The perimeter alarm chime is inoperative

|

|

GO to Pinpoint Test BD

|

|

The PRNDL not in park warning chime is inoperative

|

|

-

With the ignition OFF, the headlamps in the PARKING LAMPS position and the doors closed, OPEN the driver door and VERIFY the

headlamps on warning chime sounds.

-

If the headlamps on chime sounds, DIAGNOSE the PRNDL indicator.

GO to Pinpoint Test Z

-

If the headlamps on chime does not sound, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

The safety belt warning chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test BE

|

|

The service AdvanceTrac® chime is inoperative

|

-

Stability-traction control concern

-

|

-

With the ignition OFF, the headlamps in the PARKING LAMPS position and the doors closed, OPEN the driver door and VERIFY the

headlamps on warning chime sounds.

-

If the headlamps on chime sounds, DIAGNOSE the stability-traction control indicator.

GO to Pinpoint Test AB

-

If the headlamps on chime does not sound, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

The turn signal-hazard on warning chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test BF

|

|

The turn signal left on chime is inoperative

|

Refer to the Pinpoint Test

|

GO to Pinpoint Test BF

|

Pinpoint Tests

The

Is Inoperative/Multiple Gauges, Indicators, Message Center Indicators, Warnings And Chimes Are Inoperative Or Always On

Normal Operation and Fault Conditions

See

component description.

REFER to:

Instrument Panel Cluster (IPC) - System Operation and Component Description

(413-01 Instrumentation, Message Center and Warning Chimes, Description and Operation).

The

receives a hot at all times voltage from the

. The

receives the ignition status message for the RUN/START or ACC input from the

over the High Speed Controller Area Network (HS-CAN).

Possible Sources

-

Fuse

-

Communication concern

-

-

Visual Inspection and Diagnostic Pre-checks

Inspect the

fuse 13 (7.5A).

PINPOINT TEST A : THE IPC (INSTRUMENT PANEL CLUSTER)

IS INOPERATIVE/MULTIPLE GAUGES, INDICATORS, MESSAGE CENTER INDICATORS, WARNINGS AND CHIMES ARE INOPERATIVE OR ALWAYS ON

| A1

PERFORM THE NETWORK TEST FOR ALL MODULES

|

-

Using a diagnostic scan tool, perform a network test.

Do all equipped modules pass the network test?

|

| A2

CHECK THE GWM (GATEWAY MODULE A)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Using a diagnostic scan tool, check the

Continuous Memory Diagnostic Trouble Codes (DTCs).

Are any Diagnostic Trouble Codes (DTCs) recorded?

|

| A3

PERFORM THE IPC (INSTRUMENT PANEL CLUSTER)

SELF-TEST

|

-

Using a diagnostic scan tool, perform the

self-test.

-

Check for recorded Diagnostic Trouble Codes (DTCs) from the

self-test.

Are any Diagnostic Trouble Codes (DTCs) recorded?

| Yes

|

REFER to

Chart:

in this section.

|

| No

|

INSTALL a new

.

REFER to:

Gateway Module A (GWM)

(418-00 Module Communications Network, Removal and Installation).

TEST the system for normal operation. If the

is still inoperative, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

|

A Virtual Gauge (

, Tachometer Or Temperature), Is Inoperative

Normal Operation and Fault Conditions

See Accessory Power Gauge, Brake Coach Gauge, Consumption Gauge, High Voltage Battery Gauge, Integrated Power Gauge, Split

Power Gauge and Tachometer.

REFER to:

Instrument Panel Cluster (IPC) - System Operation and Component Description

(413-01 Instrumentation, Message Center and Warning Chimes, Description and Operation).

Gauge

-

If the

data or vehicle speed messages are missing for 5 seconds or less or if the

receives invalid torque data for 5 seconds or less, the

defaults the display fill area in front of the front wheels and behind the rear wheels to the last setting based upon that

last message received.

-

If the

does not receive the

data or vehicle speed messages for more than 5 seconds, the

defaults the display fill area in front of the front wheels and behind the rear wheels off.

Tachometer

-

If the engine rpm data message is missing for less than 5 seconds, the

defaults the tachometer to the last indication state, based upon the last message received.

-

If the engine rpm data message is missing for 5 seconds or longer, the

defaults the tachometer to 0 rpm.

Temperature Gauge

-

If the engine coolant temperature data, engine overheat indication request, heater core temperature or engine off temperature

data messages are missing for less than 5 seconds, the

defaults the temperature gauge to the last indication state, based upon the last message received.

-

If the engine coolant temperature data, engine overheat indication request, heater core temperature or engine off temperature

data messages are missing for 5 seconds or longer, the

defaults the temperature gauge to the full hot position.

Possible Sources

-

Communication concern

-

input concern

-

PINPOINT TEST B : A VIRTUAL GAUGE (AWD (ALL-WHEEL DRIVE)

, TACHOMETER OR TEMPERATURE), IS INOPERATIVE

| B1

VERIFY THE IPC (INSTRUMENT PANEL CLUSTER)

IS SET TO DISPLAY THE GAUGE

|

-

NOTE:

The

and message center navigation can be found in the Owner's Literature.

Using the message center controls, make sure the

is set to display the gauge in question.

Is the

set to display the gauge?

| No

|

The virtual gauge is operating correctly. The

was not set to display the gauge in question.

|

|

| B2

PERFORM THE IPC (INSTRUMENT PANEL CLUSTER)

SELF-TEST

|

-

Using a diagnostic scan tool, perform the

self-test.

-

Check for recorded Diagnostic Trouble Codes (DTCs) from the

self-test.

Are any Diagnostic Trouble Codes (DTCs) recorded?

| Yes

|

REFER to

Chart:

in this section.

|

| No

|

For the

gauge, tachometer or temperature gauge, GO to

B3

|

|

| B3

PERFORM THE PCM (POWERTRAIN CONTROL MODULE)

SELF-TEST

|

-

Using a diagnostic scan tool, perform the

self-test.

-

Check for recorded Diagnostic Trouble Codes (DTCs).

Are any Diagnostic Trouble Codes (DTCs) recorded?

| Yes

|

Refer to the appropriate section in Group 303 for the procedure.

|

|

| B4

PERFORM THE BCM (BODY CONTROL MODULE)

SELF-TEST

|

-

Using a diagnostic scan tool, perform the

self-test.

-

Check for recorded Diagnostic Trouble Codes (DTCs) from the

self-test.

Are any Diagnostic Trouble Codes (DTCs) recorded?

|

| B5

CHECK THE GWM (GATEWAY MODULE A)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Using a diagnostic scan tool, check the

Continuous Memory Diagnostic Trouble Codes (DTCs).

Are any Diagnostic Trouble Codes (DTCs) recorded?

|

Incorrect Fuel Gauge Indication - Single Sender L-Shaped Fuel Tank

Refer to Wiring Diagrams Cell 60 for schematic and connector information.

Normal Operation and Fault Conditions

See Fuel Gauge and Fuel Level Sender.

REFER to:

Instrument Panel Cluster (IPC) - System Operation and Component Description

(413-01 Instrumentation, Message Center and Warning Chimes, Description and Operation).

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

P0460:11

|

Fuel Level Sensor "A" Circuit: Circuit Short To Ground

|

A continuous and on-demand

that sets in the

if the fuel level input is pulled low out of range on the fuel level input circuit indicating a short to ground for 33 seconds

or longer. The

defaults the fuel gauge to empty (E).

|

|

P0460:13

|

Fuel Level Sensor "A" Circuit: Circuit Open

|

A continuous and on-demand

that sets in the

if the fuel level input is sent high out of range on the fuel level input circuit indicating an open or short to voltage

for 33 seconds or longer. The

defaults the fuel gauge to empty (E).

|

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

P0460

|

Fuel Level Sensor "A" Circuit

|

Sets when the

determines the value of the fuel level input signal is stuck, that the fuel level input signal does not change or does not

correspond with the calculated fuel usage. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P0461

|

Fuel Level Sensor "A" Circuit Range/Performance

|

Sets when the

determines the fuel level input signal repeatedly moves in and out of range, exceeding the minimum or maximum allowable calibrated

parameters for a specified fuel fill percentage in the fuel tank. Follow the pinpoint test using the Diagnostic Trouble Codes

(DTCs) set in the

.

|

|

P0462

|

Fuel Level Sensor "A" Circuit Low

|

Sets in the

when the

detects a short to ground on the fuel pump assembly signal circuit based on the messaged input received from the

. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P0463

|

Fuel Level Sensor "A" Circuit High

|

Sets in the

when the

detects an open or a short to voltage on the fuel pump assembly signal circuit based on the messaged input received from

the

. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P25B0

|

Fuel Level Sensor "A" Stuck

|

Sets when the

determines the value of the fuel level input signal is stuck, that the fuel level input signal does not change or does not

correspond with the calculated fuel usage. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P25B2

|

Fuel Level Sensor "A" or "B" Stuck

|

Sets when the

determines the value of either fuel level input signals is stuck, that the fuel level input signal does not change or does

not correspond with the calculated fuel usage. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

Possible Sources

-

Wiring, terminals or connectors

-

Fuel pump assembly

-

Fuel level sender (float and card)

-

Fuel level sensor

-

Fuel tank

-

Visual Inspection and Diagnostic Pre-checks

Inspect the fuel tank for signs of damage that can affect the float operation inside the tank. For the analog fuel gauge,

inspect the gauge needle for signs of binding or damage.

PINPOINT TEST C : INCORRECT FUEL GAUGE INDICATION - SINGLE SENDER L-SHAPED FUEL TANK

| NOTE:

Following any fuel gauge repairs, remove

fuse 13 (7.5A) for one minute then reinstall to reset the fuel gauge timers.

|

| C1

CARRY OUT THE IPC (INSTRUMENT PANEL CLUSTER)

SELF-TEST

|

-

Using a diagnostic scan tool, perform the

self-test.

-

Check for recorded Diagnostic Trouble Codes (DTCs) from the

self-test.

Are any Diagnostic Trouble Codes (DTCs) recorded?

| Yes

|

For

P0460:11, GO to

C2

For

P0460:13, GO to

C5

|

|

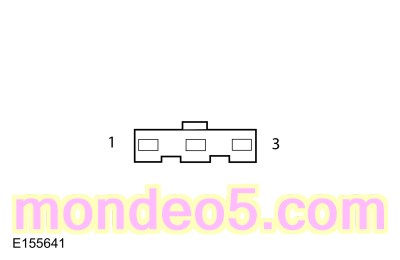

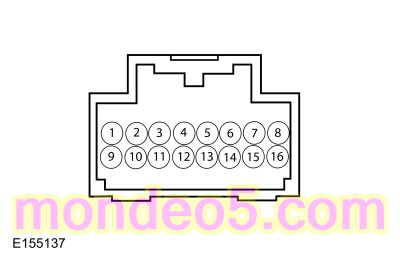

| C2

CHECK THE FUEL LEVEL INPUT FOR A SHORT TO GROUND

|

-

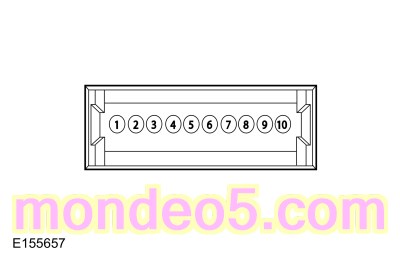

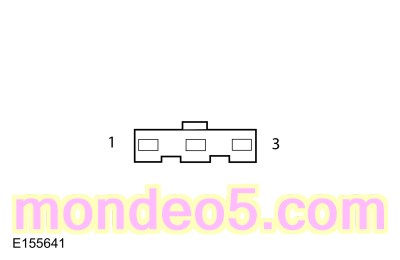

Disconnect Fuel Pump Assembly C3127

.

-

NOTE:

P0460:11 can also be present when carrying out this step and should be disregarded at this time.

Using a diagnostic scan tool, repeat the

on-demand self-test.

Is

P0460:13 present?

|

| C3

CHECK THE FUEL PUMP ASSEMBLY SIGNAL CIRCUIT FOR A SHORT TO GROUND AT THE IPC (INSTRUMENT PANEL CLUSTER)

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C220-15

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

| No

|

REPAIR the circuit in question.

|

|

| C4

CHECK THE FUEL PUMP ASSEMBLY SIGNAL AND RETURN CIRCUITS FOR A SHORT TOGETHER AT THE IPC (INSTRUMENT PANEL CLUSTER)

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C220-15

|

|

C220-2

|

Is the resistance greater than 10,000 ohms?

|

| C5

CHECK THE FUEL PUMP ASSEMBLY FOR AN OPEN

|

-

Disconnect Fuel Pump Assembly C3127

.

-

Connect a fused jumper wire:

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C3127-1

|

|

C3127-2

|

-

NOTE:

P0460:13 can also be present when carrying out this step and should be disregarded at this time.

Using a diagnostic scan tool, repeat the

self-test.

Is

P0460:11 present?

|

| C6

CHECK THE FUEL LEVEL SIGNAL CIRCUIT FOR A SHORT TO VOLTAGE AT THE IPC (INSTRUMENT PANEL CLUSTER)

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C220-15

|

|

Ground

|

Is any voltage present?

|

| C7

CHECK THE FUEL LEVEL SIGNAL CIRCUIT FOR AN OPEN BETWEEN THE IPC (INSTRUMENT PANEL CLUSTER)

AND THE FUEL PUMP ASSEMBLY

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C220-15

|

|

C3127-2

|

Is the resistance less than 3 ohms?

|

| C8

CHECK THE FUEL LEVEL RETURN CIRCUIT FOR AN OPEN BETWEEN THE IPC (INSTRUMENT PANEL CLUSTER)

AND THE FUEL PUMP ASSEMBLY

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C220-2

|

|

C3127-1

|

Is the resistance less than 3 ohms?

|

| C9

CHECK THE FUEL PUMP ASSEMBLY INPUT TO THE IPC (INSTRUMENT PANEL CLUSTER)

|

|

NOTE:

Since the

may be in anti-slosh fuel indication mode, the self-test and tester values may not match the fuel gauge readings. Disregard

the actual gauge indication during this test step.

-

Disconnect Fuel Pump Assembly C3127

.

-

Connect the universal gauge tester:

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C3127-1

|

|

C3127-2

|

-

Using a diagnostic scan tool, view the

Parameter Identifications (PIDs).

-

NOTE:

It is extremely important to confirm the gauge tester settings with an ohmmeter to make sure the gauge tester is in the correct

position. Failure to follow this check may result in inaccurate test results.

Select the

fuel level (FUELLVL1)

.

-

Monitor the

, with the gauge tester set at 180 ohms, 90 ohms, 55 ohms, 30 ohms and 10 ohms.

Does the

begin at approximately 3, move to 70, 127, 185 then 251?

| Yes

|

DISCONNECT the instrument gauge system tester. GO to

C11

|

| No

|

DISCONNECT the instrument gauge system tester. GO to

C10

|

|

| C10

CHECK THE FUEL PUMP ASSEMBLY SIGNAL AND RETURN CIRCUITS FOR HIGH RESISTANCE

|

-

Connect a fused jumper wire:

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C3127-1

|

|

C3127-2

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C220-15

|

|

C220-2

|

Is the resistance less than 3 ohms?

| Yes

|

REMOVE the fused jumper wire. GO to

C15

|

| No

|

REMOVE the fused jumper wire. REPAIR the circuits for high resistance.

|

|

| C11

INSPECT THE FUEL TANK

|

-

Visually inspect the fuel tank for any damage or deformation.

Is the fuel tank OK?

| No

|

INSTALL a new fuel tank. Refer to the appropriate section in Group 310 for the procedure.

|

|

| C12

CHECK THE FUEL PUMP ASSEMBLY

|

-

Disconnect and inspect the fuel pump assembly connector.

-

Repair:

-

corrosion (install new connector or terminals-clean module pins)

-

damaged pins-install new terminals/pins

-

pushed-out pins-install new pins as necessary

-

Reconnect the fuel pump assembly connector. Make sure it seats and latches correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| No

|

The system is operating correctly at this time. The concern may have been caused by component connections. ADDRESS the root

cause of any connector or pin issues.

|

|

| C13

CHECK THE FUEL PUMP MODULE

|

|

NOTE:

The fuel pump module resistance measures between 10 ohms ± 2 ohms at the upper stop position and 180 ohms ± 4 ohmsat the lower

stop position.

-

Remove the fuel pump module.

-

While moving the float arm from the lower stop position to the upper stop position measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

C3127-1, component side.

C3127-1, component side.

|

|

C3127-2, component side.

C3127-2, component side.

|

Does the resistance slowly decrease from approximately 180 ohms to 10 ohms?

| Yes

|

CHECK the fuel pump module connector for corrosion, damaged or pushed out pins and REPAIR as necessary. TEST the system for

normal operation.

|

|

| C14

CHECK THE FUEL PUMP ASSEMBLY FOR CORRECT OPERATION

|

-

Disconnect the fuel level sender (float and card) input wire from the fuel pump assembly.

-

Measure the resistance between the fuel level sender (float and card) input wire and the fuel level sender (float and card)

ground while slowly moving the float arm between the lower and upper stop position.

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

Fuel Level Sensor (Component Side) - Pin 1

Fuel Level Sensor (Component Side) - Pin 1

|

|

Fuel Level Sensor (Component Side) - Pin 2

Fuel Level Sensor (Component Side) - Pin 2

|

Does the resistance slowly decrease from approximately 180 ohms at the lower stop to 10 ohms at the upper stop?

| Yes

|

INSTALL a new fuel pump assembly. Refer to the appropriate section in Group 310 for the procedure.

|

| No

|

INSTALL a new fuel level sender (float and card). Refer to the appropriate section in Group 310 for the procedure.

|

|

| C15

CHECK FOR CORRECT IPC (INSTRUMENT PANEL CLUSTER)

OPERATION

|

-

Disconnect and inspect

connector.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Reconnect the

connector. Make sure it seats and latches correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Instrument Panel Cluster (IPC)

(413-01 Instrumentation, Message Center and Warning Chimes, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

Incorrect Fuel Gauge Indication - Dual Sender Saddle-Type Fuel Tank

Refer to Wiring Diagrams Cell 60 for schematic and connector information.

Normal Operation and Fault Conditions

See Fuel Gauge and Fuel Level Sender.

REFER to:

Instrument Panel Cluster (IPC) - System Operation and Component Description

(413-01 Instrumentation, Message Center and Warning Chimes, Description and Operation).

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

P0460:11

|

Fuel Level Sensor "A" Circuit: Circuit Short To Ground

|

A continuous and on-demand

that sets in the

if the fuel level input is pulled low out of range on the fuel level input circuit indicating a short to ground for 33 seconds

or longer. The

defaults the fuel gauge to empty (E).

|

|

P0460:13

|

Fuel Level Sensor "A" Circuit: Circuit Open

|

A continuous and on-demand

that sets in the

if the fuel level input is sent high out of range on the fuel level input circuit indicating an open or short to voltage

for 33 seconds or longer. The

defaults the fuel gauge to empty (E).

|

|

P1243:06

|

Second Fuel Pump Fault or Ground Fault: Algorithm Based Failure

|

Sets when the

detects a large discrepancy in the amount of fuel (based on input from the both fuel sensors) between both sides of the fuel

tank.

|

|

P1346:11

|

Fuel Level Sensor "B" Circuit: Circuit Short To Ground

|

A continuous and on-demand

that sets in the

if the

detects that the fuel level sensor is out of range on the fuel level input circuit with a short to ground for 33 seconds.

The

defaults the fuel gauge to empty (E), once the

detects a fault and sets

P1346:11.

|

|

P1346:13

|

Fuel Level Sensor "B" Circuit: Circuit Open

|

A continuous and on-demand

that sets in the

if the

detects that the fuel level sensor is out of range on the fuel level sensor input circuit with an open or short to voltage

for 33 seconds. The

defaults the fuel gauge to empty (E), once the

detects a fault and sets

P1346:13.

|

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

P0460

|

Fuel Level Sensor "A" Circuit

|

Sets when the

determines the value of the fuel level input signal is stuck, that the fuel level input signal does not change or does not

correspond with the calculated fuel usage. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P0461

|

Fuel Level Sensor "A" Circuit Range/Performance

|

Sets when the

determines the fuel level input signal repeatedly moves in and out of range, exceeding the minimum or maximum allowable calibrated

parameters for a specified fuel fill percentage in the fuel tank. Follow the pinpoint test using the Diagnostic Trouble Codes

(DTCs) set in the

.

|

|

P0462

|

Fuel Level Sensor "A" Circuit Low

|

Sets in the

when the

detects a short to ground on the fuel pump assembly signal circuit based on the messaged input received from the

. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P0463

|

Fuel Level Sensor "A" Circuit High

|

Sets in the

when the

detects an open or a short to voltage on the fuel pump assembly signal circuit based on the messaged input received from

the

. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P2065

|

Fuel Level Sensor B Circuit

|

Sets when the

determines the value of the fuel level input signal is stuck, that the fuel level input signal does not change or does not

correspond with the calculated fuel usage. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P2066

|

Fuel Level Sensor "B" Circuit Range/Performance

|

Sets when the

determines the fuel level input signal repeatedly moves in and out of range, exceeding the minimum or maximum allowable calibrated

parameters for a specified fuel fill percentage in the fuel tank. Follow the pinpoint test using the Diagnostic Trouble Codes

(DTCs) set in the

.

|

|

P2067

|

Fuel Level Sensor "B" Circuit Low

|

Sets in the

when the

detects a short to ground on the fuel level sensor signal circuit based on the messaged input received from the

. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P2068

|

Fuel Level Sensor "B" Circuit High

|

Sets in the

when the

detects an open or a short to voltage on the fuel level sensor signal circuit based on the messaged input received from the

. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P25B0

|

Fuel Level Sensor "A" Stuck

|

Sets when the

determines the value of the fuel level input signal is stuck, that the fuel level input signal does not change or does not

correspond with the calculated fuel usage. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P25B1

|

Fuel Level Sensor "B" Stuck

|

Sets when the

determines the value of the fuel level input signal is stuck, that the fuel level input signal does not change or does not

correspond with the calculated fuel usage. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

|

P25B2

|

Fuel Level Sensor "A" or "B" Stuck

|

Sets when the

determines the value of either fuel level input signals is stuck, that the fuel level input signal does not change or does

not correspond with the calculated fuel usage. Follow the pinpoint test using the Diagnostic Trouble Codes (DTCs) set in the

.

|

Possible Sources

-

Wiring, terminals or connectors

-

Fuel pump assembly

-

Fuel level sender (float and card)

-

Fuel level sensor

-

Fuel tank

-

Visual Inspection and Diagnostic Pre-checks

Inspect the fuel tank for signs of damage that can affect the float operation inside the tank. For the analog fuel gauge,

inspect the gauge needle for signs of binding or damage.

PINPOINT TEST D : INCORRECT FUEL GAUGE INDICATION - DUAL SENDER SADDLE-TYPE FUEL TANK

| NOTE:

Following any fuel gauge repairs, remove

fuse 13 (7.5A) for one minute then reinstall to reset the fuel gauge timers.

|

| D1

CARRY OUT THE IPC (INSTRUMENT PANEL CLUSTER)

SELF-TEST

|

-

Using a diagnostic scan tool, perform the

self-test.

-

Check for recorded Diagnostic Trouble Codes (DTCs) from the

self-test.

Are any Diagnostic Trouble Codes (DTCs) recorded?

| Yes

|

For

P0460:11 or P1346:11, GO to

D2

For

P0460:13 or P1346:13, GO to

D6

For

P1243:06, GO to

D14

|

|

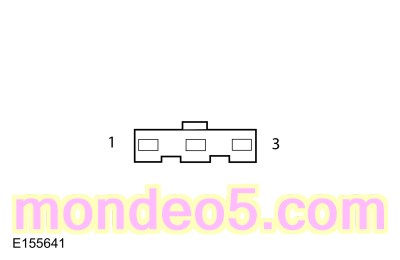

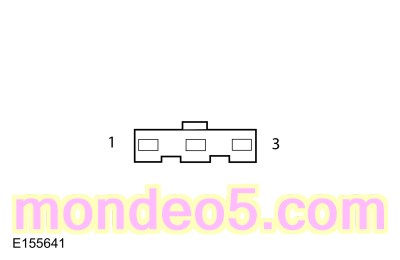

| D2

CHECK THE FUEL INPUT FOR A SHORT TO GROUND

|

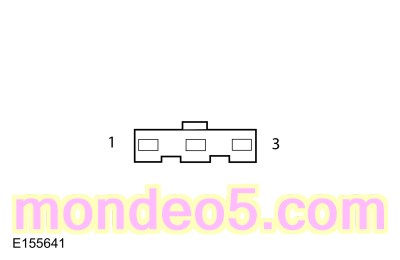

-

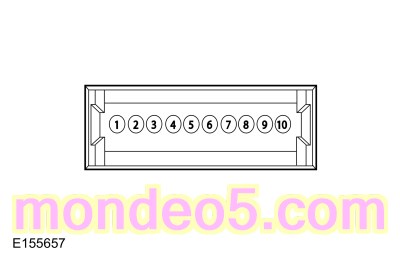

Disconnect Fuel Pump Assembly C3127 (

P0460:11).

-

Disconnect Fuel Level Sensor C3270 (

P1346:11).

-

NOTE:

P0460:11 or P1346:11 can also be present when carrying out this step and should be disregarded at this time.

Using a diagnostic scan tool, repeat the

on-demand self-test.

Is

P0460:13 or P1346:13 present?

| Yes

|

For the fuel pump assembly (

P0460:11), GO to

D20

For the fuel level sensor (

P1346:11), INSTALL a new fuel level sensor. Refer to the appropriate section in Group 310 for the procedure.

|

|

| D3

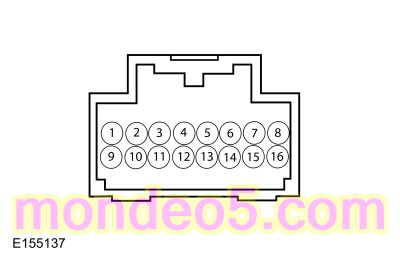

CHECK THE FUEL PUMP ASSEMBLY AND FUEL LEVEL SENSOR SIGNAL CIRCUIT FOR A SHORT TO GROUND AT THE IPC (INSTRUMENT PANEL CLUSTER)

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C220-15 (

P0460:11)

|

|

Ground

|

|

C220-14 (

P1346:11)

|

|

Ground

|

Are the resistances greater than 10,000 ohms?

| Yes

|

For

P0460:11, GO to

D4

For

P1346:11, GO to

D5

|

| No

|

REPAIR the circuit in question.

|

|

| D4

CHECK THE FUEL PUMP ASSEMBLY SIGNAL AND RETURN CIRCUITS FOR A SHORT TOGETHER AT THE IPC (INSTRUMENT PANEL CLUSTER)

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C220-15

|

|

C220-2

|

Is the resistance greater than 10,000 ohms?

|

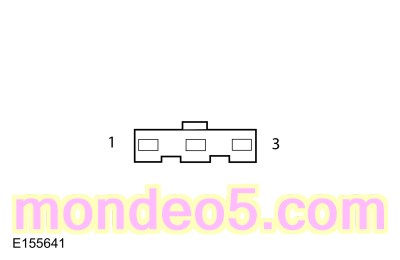

| D5

CHECK THE FUEL LEVEL SENSOR SIGNAL AND RETURN CIRCUITS FOR A SHORT TOGETHER AT THE IPC (INSTRUMENT PANEL CLUSTER)

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C220-14

|

|

C220-1

|

Is the resistance greater than 10,000 ohms?

|

| D6

CHECK THE FUEL PUMP ASSEMBLY OR FUEL LEVEL SENSOR FOR AN OPEN

|

-

Disconnect Fuel Pump Assembly C3127 (

P0460:13).

-

Disconnect Fuel Level Sensor C3270 (

P1346:13).

-

Connect a fused jumper wire:

P0460:13

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C3127-1

|

|

C3127-2

|

P1346:13

|

Lead 1

|

Measurement / Action

|

Lead 2

|

|

C3270-1

|

|

C3270-2

|

-

NOTE:

P0460:13 or P1346:13 can also be present when carrying out this step and should be disregarded at this time.

Using a diagnostic scan tool, repeat the

self-test.

Is

P0460:11 or P1346:11 present?

| Yes

|

REMOVE the fused jumper wire. For

P0460:13, GO to

D7

|

| No

|

REMOVE the fused jumper wire. For

P1346:13, GO to

D10

|

|

| D7

CHECK THE FUEL LEVEL SIGNAL CIRCUIT FOR A SHORT TO VOLTAGE AT THE IPC (INSTRUMENT PANEL CLUSTER)

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C220-15

|

|

Ground

|