| 211-05 Steering Wheel and Column Electrical Components

|

2013 - 2014 Fusion

|

| Diagnosis and Testing

|

Procedure revision date:

06/7/2013

|

Steering Wheel and Column Electrical Components

DTC Charts

Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

|

|

Description

|

Action

|

|

B108A:01

|

Start Button: General Electrical Failure

|

GO to Pinpoint Test E

|

|

B108A:24

|

Start Button: Signal Stuck High

|

GO to Pinpoint Test E

|

|

B1142:29

|

Ignition Status 1: Signal Invalid

|

For vehicles equipped with an ignition switch,

GO to Pinpoint Test C

For vehicles equipped with push button start,

GO to Pinpoint Test E

|

|

B1240:11

|

Start Button Mode Indicator: Circuit Short to Ground

|

REFER to:

Instrument Panel Cluster (IPC) and Panel Illumination

(413-00 Instrument Panel Cluster (IPC) and Panel Illumination, Diagnosis and Testing).

|

|

B1240:15

|

Start Button Mode Indicator: Circuit Short to Battery or Open

|

REFER to:

Instrument Panel Cluster (IPC) and Panel Illumination

(413-00 Instrument Panel Cluster (IPC) and Panel Illumination, Diagnosis and Testing).

|

|

B130F:12

|

Run Accessory Control: Circuit Short to Battery

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B130F:14

|

Run Accessory Control: Circuit Short to Ground or Open

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1310:12

|

Run/Start Control: Circuit Short to Battery

|

GO to Pinpoint Test J

|

|

B1310:14

|

Run/Start Control: Circuit Short to Ground or Open

|

For vehicles equipped with an ignition switch,

GO to Pinpoint Test C

For vehicles equipped with push button start,

GO to Pinpoint Test E

|

|

U0212:87

|

Lost Communication With Steering Column Control Module: Missing Message

|

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

|

U300A:01

|

Ignition Switch: General Electrical Failure

|

GO to Pinpoint Test A

|

|

All other Diagnostic Trouble Codes (DTCs)

|

-

|

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

|

|

Description

|

Action

|

|

B1007:09

|

High-Beam Headlamp Switch: Component Failure

|

REFER to:

Headlamps

(417-01 Exterior Lighting, Diagnosis and Testing).

|

|

B1008:09

|

Wiper Mode Switch: Component Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1051:09

|

Front Washer Switch: Component Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1052:09

|

Rear Washer Switch: Component Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B10AD:02

|

Rain Sensor: General Signal Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B10AD:08

|

Rain Sensor: Bus Signal/Message Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B10AD:49

|

Rain Sensor: Internal Electronic Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B10AD:55

|

Rain Sensor: Not Configured

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:02

|

Wiper motor module: General Signal Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:08

|

Wiper motor module: Bus Signal/Message Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:11

|

Wiper motor module: Circuit Short To Ground

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:49

|

Wiper motor module: Internal Electronic Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:55

|

Wiper motor module: Not Configured

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B1131:9A

|

Wiper motor module: Component or System Operating Conditions

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B11D9:16

|

Vehicle Battery: Circuit Voltage Below Threshold

|

GO to Pinpoint Test H

|

|

B11D9:17

|

Vehicle Battery: Circuit Voltage Above Threshold

|

GO to Pinpoint Test I

|

|

B12F7:09

|

Single Wipe Switch: Component Failure

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

|

B137F:09

|

Steering Wheel Left Switch Pack: Component Failure

|

REFER to:

Cruise Control

(419-03A Cruise Control, Diagnosis and Testing).

|

|

B137F:11

|

Steering Wheel Left Switch Pack: Circuit Short to Ground

|

REFER to:

Cruise Control

(419-03A Cruise Control, Diagnosis and Testing).

|

|

B137F:17

|

Steering Wheel Left Switch Pack: Circuit Voltage Above Threshold

|

REFER to:

Cruise Control

(419-03A Cruise Control, Diagnosis and Testing).

|

|

B1380:09

|

Steering Wheel Right Switch Pack: Component Failure

|

REFER to:

|

|

B1380:11

|

Steering Wheel Right Switch Pack: Circuit Short to Ground

|

REFER to:

|

|

B1380:17

|

Steering Wheel Right Switch Pack: Circuit Voltage Above Threshold

|

REFER to:

|

|

B13A6:09

|

Lane Departure Warning (LDW) Switch Input: Component Failure

|

REFER to:

Lane Departure Warning

(419-07 Lane Departure Warning, Diagnosis and Testing).

|

|

B1D36:09

|

Turn Indicator Switch: Component Failure

|

REFER to:

Turn Signal and Hazard Lamps

(417-01 Exterior Lighting, Diagnosis and Testing).

|

|

U2100:00

|

Initial Configuration Not Complete: No Sub Type Information

|

Check vehicle service history for recent service actions related to this module. This

will set due to incomplete or improper PMI (Programmable Module Installation) procedures. If there have been recent service

actions with this module, REPEAT/PERFORM the PMI procedure as directed by the diagnostic scan tool. If there have been no

recent service actions, INSTALL a new module to correct the failure to retain configuration data.

|

|

U2101:00

|

Control Module Configuration Incompatible: No Sub Type Information

|

This

sets if the steering wheel switches do not match the switch function configuration data in the

. CHECK the parts catalog and CONFIRM that the correct

and steering wheel control switches are installed in the vehicle. INSTALL the correct components, as necessary.

|

Chart

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Symptom Chart

Symptom Chart: Steering Column Switches

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices.

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Symptom Chart

|

Condition

|

Possible Causes

|

Actions

|

|

No power in all ignition switch positions - conventional ignition switch

|

Refer to Pinpoint Test

|

GO to Pinpoint Test A

|

|

No power in ACC - conventional ignition switch

|

Refer to Pinpoint Test

|

GO to Pinpoint Test B

|

|

No power in RUN - conventional ignition switch

|

Refer to Pinpoint Test

|

GO to Pinpoint Test C

|

|

No power in START - conventional ignition switch

|

Refer to Pinpoint Test

|

GO to Pinpoint Test D

|

|

No power in ON - push button ignition switch

|

Refer to Pinpoint Test

|

GO to Pinpoint Test E

|

|

Key not detected is displayed in the message center

|

-

Wiring, terminals or connectors

-

Passive key

-

antennas

-

module

|

REFER to:

Passive Anti-Theft System (PATS)

(419-01C Passive Anti-Theft System (PATS) - Vehicles With: Push Button Start, Diagnosis and Testing).

|

|

The ignition key cannot be returned to the OFF position

|

Refer to Pinpoint Test

|

GO to Pinpoint Test F

|

|

The ignition key can be turned to the OFF position when the selector lever is not in PARK

|

Refer to Pinpoint Test

|

GO to Pinpoint Test G

|

|

The ignition key is hard to turn

|

-

Ignition lock cylinder

-

Ignition key

-

Ignition switch

|

REFER to:

Locks, Latches and Entry Systems

(501-14 Handles, Locks, Latches and Entry Systems, Diagnosis and Testing).

|

|

The multifunction switch does not operate correctly

|

|

REFER to:

Autolamps

(417-01 Exterior Lighting, Diagnosis and Testing).

|

|

The wiper and washer switch does not operate correctly

|

|

REFER to:

Wipers and Washers

(501-16 Wipers and Washers, Diagnosis and Testing).

|

Pinpoint Tests

No Power in All Ignition Switch Positions - Conventional Ignition Switch

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

The ignition switch receives fused battery voltage from

fuse 18 (5A). In the ACC or ON position, this voltage is sent through the ignition switch and back to the

. In the START position, this voltage is sent through the ignition switch and then to both the

and the

.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

U300A:01

|

Ignition Switch: General Electrical Failure

|

The

continuously monitors the ignition switch position. This

sets if the voltage inputs to the

do not match the pre-defined configurations for each ignition switch position.

|

Possible Causes

-

Fuse(s)

-

Wiring, terminals or connectors

-

Ignition switch

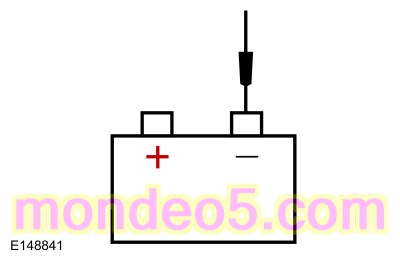

Visual Inspection and Diagnostic Pre-checks

-

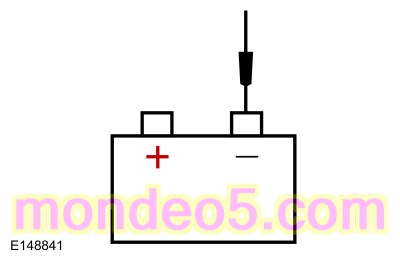

Inspect the battery and battery cables.

-

Inspect high current

MEGA fuse 2 (125A).

-

Inspect

fuse 18 (5A).

PINPOINT TEST A : NO POWER IN ALL IGNITION SWITCH POSITIONS - CONVENTIONAL IGNITION SWITCH

| A1

CHECK THE IGNITION SWITCH

|

-

Disconnect Ignition Switch C250

.

-

Carry out the ignition switch component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

Is the ignition switch OK?

| No

|

INSTALL a new ignition switch.

REFER to:

Ignition Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| A2

CHECK THE VEHICLE BATTERY

|

-

Carry out the Battery Condition Test.

REFER to:

Battery

(414-01 Battery, Mounting and Cables, Diagnosis and Testing).

Is the battery OK?

|

| A3

CHECK FOR POWER TO THE IGNITION SWITCH

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C250-4

|

|

Ground

|

Is the voltage greater than 11 volts?

| No

|

VERIFY

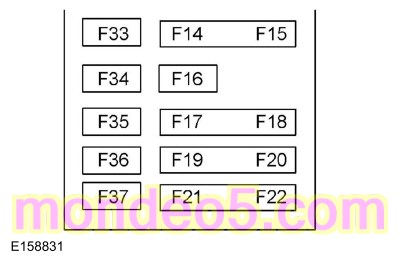

fuse 18 (5A) is OK. If OK, GO to

A4

If not OK, REFER to the Wiring Diagrams manual to identify the possible cause of the circuit short.

|

|

| A4

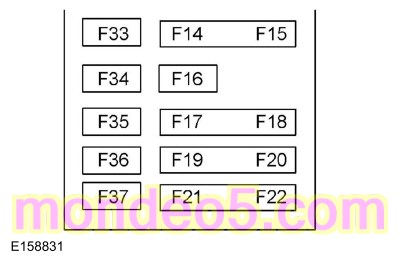

CHECK FOR POWER TO BODY CONTROL MODULE (BCM) FUSE 18 (5A)

|

-

Verify

fuse 18 (5A) is installed.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

CFUSE-18 (5A)

CFUSE-18 (5A)

|

|

Ground

|

Is the voltage greater than 11 volts?

| Yes

|

REPAIR the circuit between

fuse 18 (5A) and ignition switch C250.

|

| No

|

VERIFY high current

MEGA fuse 2 (125A) is OK. If OK, REPAIR the

voltage supply circuit. If not OK, REFER to the Wiring Diagrams manual to identify the possible cause of the circuit short.

|

|

| A5

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

No Power in ACC - Conventional Ignition Switch

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

When in ACC mode, the ignition switch sends voltage to the

. The

then sends out an ignition status message to the other modules on the

.

Possible Causes

-

Wiring, terminals or connectors

-

Ignition switch

-

PINPOINT TEST B : NO POWER IN ACC - CONVENTIONAL IGNITION SWITCH

| B1

CHECK FOR ACC VOLTAGE AT THE BCM (BODY CONTROL MODULE)

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280G-50

|

|

Ground

|

Is the voltage greater than 11 volts?

|

| B2

CHECK THE IGNITION ACC CIRCUIT FOR AN OPEN

|

-

Disconnect Ignition Switch C250

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280G-50

|

|

C250-6

|

Is the resistance less than 3 ohms?

| Yes

|

INSTALL a new ignition switch.

REFER to:

Ignition Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| B3

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

No Power in RUN - Conventional Ignition Switch

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

When the ignition switch is turned to the RUN position, a voltage signal is sent to the

. The

then activates the integral run/start relay and sends a signal to activate the

run/start relay, which distributes fused voltage to various components. The integral run/start relay in the

receives voltage from high current

MEGA fuse 2 (125A). The run/start relay in the

receives voltage from the battery through the high current

.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

B1142:29

|

Ignition Status 1: Signal Invalid

|

This

sets when the

does not receive a valid ignition signal during a

self-test.

|

|

B1310:14

|

Run/Start Control: Circuit Short to Ground or Open

|

The

continuously monitors the control side of the run/start relay in the

. This

is set if the

detects an open or a short to ground on the control circuit. When this

sets, the control side of the run/start relay is disabled via the Field-Effect Transistor (FET). Once the condition that

caused the

to set is repaired, the

must pass a self-test in order for the

to clear and the system to resume normal operation

|

Possible Causes

-

Wiring, terminals or connectors

-

Run/start relay

-

Ignition switch

-

Visual Inspection and Diagnostic Pre-checks

-

Inspect

fuse 18 (5A).

-

Inspect high current

MEGA fuse 2 (125A).

PINPOINT TEST C : NO POWER IN ON - CONVENTIONAL IGNITION SWITCH

| C1

CHECK FOR BCM (BODY CONTROL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Enter the following diagnostic mode:

Self-Test.

-

Record all

Diagnostic Trouble Codes (DTCs).

Are any Diagnostic Trouble Codes (DTCs) present?

| Yes

|

If

B1310:14 is present, GO to

C2

If

B1142:29 is present, GO to

C5

For all other

Diagnostic Trouble Codes (DTCs),

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

| No

|

If no Diagnostic Trouble Codes (DTCs) are present, GO to

C5

|

|

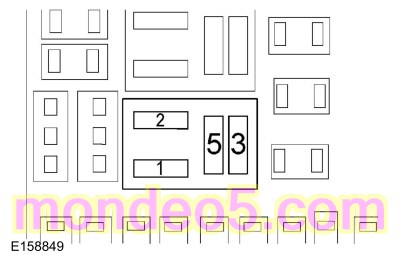

| C2

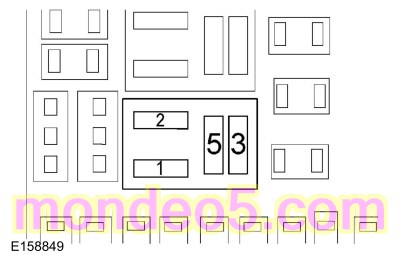

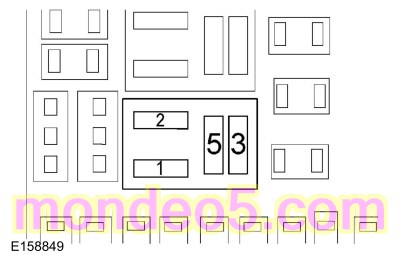

CHECK THE BJB (BATTERY JUNCTION BOX)

RUN/START RELAY

|

-

Remove the

run/start relay.

-

Carry out the appropriate relay component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

Is the relay OK?

| No

|

INSTALL a new

run/start relay.

|

|

| C3

CHECK THE RUN/START RELAY CONTROL CIRCUIT FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280C-25

|

|

Ground

|

Is the resistance less than 3 ohms?

|

| C4

CHECK THE RUN/START RELAY CONTROL CIRCUIT FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280C-25

|

|

BJB run/start relay socket, Pin 2

BJB run/start relay socket, Pin 2

|

Is the resistance less than 3 ohms?

|

| C5

CHECK FOR IGNITION ON MODE

|

|

NOTE:

The airbag warning indicator in the IPC (instrument panel cluster) only illuminates and proves out when the vehicle successfully

enters ON mode.

-

Monitor the airbag warning indicator while attempting to enter ON mode.

Did the airbag warning indicator illuminate?

|

| C6

CARRY OUT A NETWORK TEST

|

-

Enter the following diagnostic mode on the diagnostic scan tool: Network Test.

Did the

pass the Network Test?

|

| C7

CHECK THE BCM (BODY CONTROL MODULE)

IGNITION RUN/ACCESSORY OUTPUT CONTROL (IGN_ACC/RUN) PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

Does the

read On when the ignition is in the ON position?

|

| C8

CHECK THE BCM (BODY CONTROL MODULE)

IGNITION RUN/ACCESSORY INPUT CONTROL (IGN_R/A_INPT) PID (PARAMETER IDENTIFICATION)

|

-

Monitor the

IGN_R/A_INPT.

Does the

read On when the ignition is in the ON position?

| No

|

CARRY OUT the ignition switch component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

If the ignition switch tests OK, GO to

C11

If not OK, INSTALL a new ignition switch.

REFER to:

Ignition Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| C9

CHECK THE BCM (BODY CONTROL MODULE)

IGNITION RUN/START OUTPUT CONTROL (IGN_RUN/STRT) PID (PARAMETER IDENTIFICATION)

|

-

Monitor the

IGN_RUN/STRT.

Does the

read On when the ignition is in the ON position?

| Yes

|

CARRY OUT the

run/start relay component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

If the run/start tests OK, GO to

C13

If not OK, INSTALL a new run/start relay.

|

|

| C10

CHECK THE BCM (BODY CONTROL MODULE)

IGNITION RUN/START INPUT CONTROL (IGN_R/S_INPT) PID (PARAMETER IDENTIFICATION)

|

-

Monitor the

IGN_R/S_INPT.

Does the

read On when the ignition is in the ON position?

| No

|

CARRY OUT the ignition switch component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

If the ignition switch tests OK, GO to

C14

If not OK, INSTALL a new ignition switch.

REFER to:

Ignition Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| C11

CHECK FOR A SHORT TO GROUND ON THE BCM (BODY CONTROL MODULE)

ACC/RUN INPUT CIRCUIT

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280G-50

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| C12

CHECK FOR AN OPEN ON THE BCM (BODY CONTROL MODULE)

ACC/RUN INPUT CIRCUIT

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280G-50

|

|

C250-6

|

Is the resistance less than 3 ohms?

|

| C13

CHECK FOR A SHORT TO VOLTAGE ON THE RUN/START CONTROL CIRCUIT

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280C-25

|

|

Ground

|

Is any voltage present?

|

| C14

CHECK FOR A SHORT TO GROUND ON THE BCM (BODY CONTROL MODULE)

RUN/START INPUT CIRCUIT

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280G-37

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| C15

CHECK FOR AN OPEN ON THE BCM (BODY CONTROL MODULE)

RUN/START INPUT CIRCUIT

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280G-37

|

|

C250-1

|

Is the resistance less than 3 ohms?

|

| C16

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

.

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

No Power in START - Conventional Ignition Switch

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Refer to Wiring Diagrams Cell 20 for schematic and connector information.

Normal Operation and Fault Conditions

When the ignition switch is turned to the START position, a voltage signal is sent to the

and the

. The

then sends out an ignition status message on the

to indicate a start event and the

checks various inputs and bus messages in an effort to start the vehicle.

Possible Causes

-

Wiring, terminals or connectors

-

Ignition switch

PINPOINT TEST D : NO POWER IN START - CONVENTIONAL IGNITION SWITCH

| D1

CHECK THE BCM (BODY CONTROL MODULE)

IGNITION RUN/START INPUT (IGN_R/S_INPT) PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

-

While holding the key in the START position, monitor the

IGN_R/S_INPT.

Does the

read On when the ignition is in the START position?

|

| D2

CHECK THE PCM (POWERTRAIN CONTROL MODULE)

KEY POSITION FOR START INDICATED (START_KEY) PID (PARAMETER IDENTIFICATION)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Parameter Identifications (PIDs).

Does the

read On when the ignition is in the START position?

| Yes

|

DIAGNOSE the no start condition, Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual.

|

|

| D3

CHECK FOR START VOLTAGE AT THE PCM (POWERTRAIN CONTROL MODULE)

|

-

Disconnect

C1232B (1.6L GTDI).

-

Disconnect

C1381B (2.0L GTDI).

-

Disconnect

C175B (2.0L HEV).

-

Disconnect

C1551B (2.5L i-VCT).

-

While holding the key in the START position, measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1232B-47 (1.6L GTDI)

|

|

Ground

|

|

C1381B-47 (2.0L GTDI)

|

|

Ground

|

|

C175B-9 (2.0L HEV)

|

|

Ground

|

|

C1551B-16 (2.5L i-VCT)

|

|

Ground

|

Is the voltage greater than 11 volts?

| No

|

CARRY OUT the ignition switch component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

If the ignition switch tests OK, REPAIR the circuit. If not OK, INSTALL a new ignition switch.

REFER to:

Ignition Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| D4

CHECK FOR START VOLTAGE AT THE BCM (BODY CONTROL MODULE)

|

-

While holding the key in the START position, measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280H-14

|

|

Ground

|

Is the voltage greater than 11 volts?

| No

|

CARRY OUT the ignition switch component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

If the ignition switch tests OK, REPAIR the circuit. If not OK, INSTALL a new ignition switch.

REFER to:

Ignition Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| D5

CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Powertrain Control Module (PCM)

(303-14B Electronic Engine Controls - 1.6L EcoBoost (132kW/180PS) - Sigma, Removal and Installation).

REFER to:

Powertrain Control Module (PCM)

(303-14C Electronic Engine Controls - 2.0L EcoBoost (184kW/250PS) - MI4, Removal and Installation).

REFER to:

Powertrain Control Module (PCM)

(303-14D Electronic Engine Controls - 2.5L Duratec (125kW/170PS), Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

| D6

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

.

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

No Power in ON - Push Button Ignition Switch

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Refer to Wiring Diagrams Cell 20 for schematic and connector information.

Normal Operation and Fault Conditions

To place the vehicle in ON mode, locate the passive key inside the vehicle and press the ignition switch once, for at least

one second, without applying the brake pedal. When in ON mode, the

activates the integral run/start relay and provides a ground signal to activate the

run/start relay, which distributes fused voltage to various components. The integral run/start relay in the

receives voltage from high current

MEGA fuse 2 (125A). The

run/start relay receives voltage from the battery through the high current

. The

uses a Field-Effect Transistor (FET) to control the relays.

To start the engine, locate the passive key inside the vehicle, position the selector lever into PARK or NEUTRAL, and press

the ignition switch while applying the brake pedal. When the ignition switch is pressed, a voltage signal is sent to the

and

. When the

detects the ignition switch is pressed, it begins the key initialization sequence by activating the front

antenna and the keyless entry rear antenna. Once the

detects a valid passive key is present, the

supplies power and ground to the starter relay.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

B108A:01

|

Start Button: General Electrical Failure

|

Sets if the

does not receive any signal from the push button ignition switch.

|

|

B108A:24

|

Start Button: Signal Stuck High

|

Sets if the

detects a short to voltage from the Start/Stop 1 input circuit from the push button ignition switch.

|

|

B1142:29

|

Ignition Status 1: Signal Invalid

|

Sets when the

does not receive a valid ignition signal during a

self test.

|

|

B1310:14

|

Run/Start Control: Circuit Short to Ground or Open

|

The

continuously monitors the control side of the run/start relay. This

is set if the

detects an open or a short to ground on the control circuit. The

uses a Field-Effect Transistor (FET) to control the run/start relay. When this

sets, the control side of the run/start relay is disabled via the Field-Effect Transistor (FET). Once the condition that

caused the

to set is repaired, the

must pass a self-test in order for the

to clear and the system to resume normal operation.

|

Possible Causes

-

Battery

-

Wiring, terminals or connectors

-

Fuse(s)

-

Relay

-

Push button ignition switch

-

Passive key

-

Keyless entry system

-

-

Visual Inspection and Diagnostic Pre-checks

-

Inspect the battery and battery cables.

-

Inspect high current

MEGA fuse 2 (125A).

-

Inspect

fuse 18 (5A).

PINPOINT TEST E : NO POWER IN ON - PUSH BUTTON IGNITION SWITCH

| E1

CHECK FOR BCM (BODY CONTROL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Enter the following diagnostic mode:

Self-Test.

-

Record all

Diagnostic Trouble Codes (DTCs).

Are any Diagnostic Trouble Codes (DTCs) present?

| Yes

|

If

B1310:14 is present, GO to

E2

If

B108A:01, B108A:24 or B1142:29 is present, GO to

E5

For all other

Diagnostic Trouble Codes (DTCs),

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

| No

|

If no Diagnostic Trouble Codes (DTCs) are present, GO to

E5

|

|

| E2

CHECK THE BJB (BATTERY JUNCTION BOX)

RUN/START RELAY

|

-

Remove the

run/start relay.

-

Carry out the appropriate relay component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

Is the relay OK?

| No

|

INSTALL a new

run/start relay.

|

|

| E3

CHECK THE RUN/START RELAY CONTROL CIRCUIT FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280C-25

|

|

Ground

|

Is the resistance less than 3 ohms?

|

| E4

CHECK THE RUN/START RELAY CONTROL CIRCUIT FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280C-25

|

|

BJB run/start relay socket, Pin 2

BJB run/start relay socket, Pin 2

|

Is the resistance less than 3 ohms?

|

| E5

CONFIRM THE PASSIVE KEY ALLOWS VEHICLE ENTRY

|

|

NOTE:

Do not place the passive key inside the vehicle during this test step.

-

With the driver door unlocked and the passive key within 1 m (3.28 ft) of the driver door, press the button on the driver

door handle; the driver door should lock.

Did the driver door lock?

|

| E6

CHECK VEHICLE BATTERY

|

-

Carry out the Battery Condition Test.

REFER to:

Battery

(414-01 Battery, Mounting and Cables, Diagnosis and Testing).

Is the battery OK?

|

| E7

CHECK FOR IGNITION ON MODE

|

|

NOTE:

The airbag warning indicator in the message center only illuminates and proves out when the vehicle successfully enters ON

mode.

-

With the passive key in the vehicle, press the ignition switch for at least one second while monitoring the airbag warning

indicator in the message center.

Did the airbag warning indicator illuminate for approximately 6 seconds and then go out?

|

| E8

CARRY OUT A NETWORK TEST

|

-

Enter the following diagnostic mode on the diagnostic scan tool: Network Test.

Did the

pass the Network Test?

|

| E9

CHECK THE BCM (BODY CONTROL MODULE)

IGNITION SWITCH PARAMETER IDENTIFICATIONS (PIDS)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Parameter Identification (PIDs).

-

While pressing the ignition switch, monitor the following Parameter Identifications (PIDs):

-

Start_Stop_1

-

Start_Stop_2

Did both PIDs change state when the switch was pressed?

|

| E10

CHECK THE IGNITION SWITCH

|

-

Disconnect Ignition Switch C2195

.

-

Carry out the push button ignition switch component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

Does the ignition switch pass the test?

|

| E11

CHECK FOR VOLTAGE AT THE IGNITION SWITCH

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2195-4

|

|

Ground

|

Is the voltage greater than 11 volts?

| No

|

VERIFY

fuse 18 (5A) is OK. If OK, REPAIR the circuit. If not OK, REFER to the Wiring Diagrams manual to identify the possible cause

of the circuit short.

|

|

| E12

CHECK THE GROUND CIRCUIT TO THE IGNITION SWITCH

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2195-3

|

|

Ground

|

Is the resistance less than 3 ohms?

|

| E13

CHECK THE START/STOP 1 CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Disconnect

C1381B (2.0 GTDI).

-

Disconnect

C175B (2.0L HEV).

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2195-1

|

|

Ground

|

Is any voltage present?

|

| E14

CHECK THE IGNITION SWITCH CIRCUITS TO THE BCM (BODY CONTROL MODULE)

FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2195-6

|

|

Ground

|

|

C2195-1

|

|

Ground

|

Are the resistances greater than 10,000 ohms?

| No

|

REPAIR the affected circuit(s).

|

|

| E15

CHECK THE IGNITION SWITCH CIRCUITS TO THE BCM (BODY CONTROL MODULE)

FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2195-6

|

|

C2280G-5

|

|

C2195-1

|

|

C2280G-51

|

Are the resistances less than 3 ohms?

| No

|

REPAIR the affected circuit(s).

|

|

| E16

CHECK THE CIRCUIT BETWEEN THE IGNITION SWITCH AND PCM (POWERTRAIN CONTROL MODULE)

FOR AN OPEN

|

-

Measure:

2.0L HEV

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2195-1

|

|

C175B-16

|

2.0L GTDI

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2195-1

|

|

C1232B-47

|

Is the resistance less than 3 ohms?

|

| E17

CHECK FOR A SHORT BETWEEN THE IGNITION SWITCH CIRCUITS

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2195-1

|

|

C2195-6

|

Is the resistance between these circuits greater than 10,000 ohms?

|

| E18

ATTEMPT VEHICLE START WHILE MONITORING THE MESSAGE CENTER

|

-

With the vehicle in PARK (automatic transmission) or NEUTRAL (automatic or manual transmission) and the passive key in the

vehicle, press the brake pedal and then press the ignition switch while monitoring the message center.

Did the engine crank?

| Yes

|

To diagnose the no start concern, Refer to Powertrain Control/Emissions Diagnosis (PC/ED) manual.

|

| No

|

If No key detected is displayed in the message center,

REFER to:

Passive Anti-Theft System (PATS)

(419-01C Passive Anti-Theft System (PATS) - Vehicles With: Push Button Start, Diagnosis and Testing).

If there is no message displayed in the message center, GO to

E19

|

|

| E19

CARRY OUT A NETWORK TEST

|

-

Enter the following diagnostic mode on the diagnostic scan tool: Network Test.

Did the

and

pass the network test?

|

| E20

CHECK FOR PCM (POWERTRAIN CONTROL MODULE)

AND BCM (BODY CONTROL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self-Test.

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self-Test.

Are any

or

Diagnostic Trouble Codes (DTCs) present?

| Yes

|

For

Diagnostic Trouble Codes (DTCs),

REFER to:

Electronic Engine Controls

(303-14C Electronic Engine Controls - 2.0L EcoBoost (184kW/250PS) - MI4, Diagnosis and Testing).

Diagnostic Trouble Codes (DTCs),

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Diagnosis and Testing).

|

|

| E21

CHECK FOR CORRECT BODY CONTROL MODULE (BCM) OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

The Ignition Key Cannot Be Returned to the OFF Position

Refer to Wiring Diagrams Cell 37 for schematic and connector information.

Normal Operation and Fault Conditions

The key removal inhibit solenoid (part of the ignition switch) receives battery voltage from

fuse 18 (5A). When the selector lever is moved into the PARK position, the Brake Shift Interlock Actuator (BSIA) (part of

the selector lever) opens, interrupting a ground circuit to the key removal inhibit solenoid. The key removal inhibit solenoid

deactivates and allows the ignition lock cylinder to be turned to the OFF position and the key to be removed. The

also receives a ground signal from the selector lever indicating the status of the Brake Shift Interlock Actuator (BSIA).

Possible Causes

-

Wiring, terminals or connectors

-

Ignition switch (includes key inhibit solenoid)

-

Ignition lock cylinder

-

-

Selector lever (includes Brake Shift Interlock Actuator (BSIA))

PINPOINT TEST F : THE IGNITION KEY CANNOT BE RETURNED TO THE OFF POSITION

| F1

CHECK FOR AN ENERGIZED KEY REMOVAL INHIBIT SOLENOID

|

-

Attempt to turn the ignition lock cylinder to the ON position and then back to the OFF-LOCK position and remove the key.

Can the ignition lock cylinder be turned to the OFF-LOCK position and the key removed?

|

| F2

CHECK THE IGNITION SWITCH FOR MECHANICAL DAMAGE

|

-

Remove the ignition switch.

REFER to:

Ignition Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

-

Attempt to turn the ignition lock cylinder to the OFF-LOCK position and remove the ignition key.

Does the ignition lock cylinder turn to the OFF-LOCK position and can the key be removed?

| Yes

|

INSTALL a new ignition switch (includes key inhibit solenoid).

REFER to:

Ignition Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

INSTALL a new ignition lock cylinder.

REFER to:

Ignition Lock Cylinder

(501-14 Handles, Locks, Latches and Entry Systems, Removal and Installation).

|

|

| F3

CHECK THE KEY REMOVAL INHIBIT SOLENOID CIRCUIT FOR A SHORT TO GROUND

|

-

Disconnect Ignition Switch C250

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C250-3

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

| Yes

|

INSTALL a new ignition switch (includes key inhibit solenoid).

REFER to:

Ignition Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| F4

ISOLATE THE SHORT TO GROUND IN THE KEY REMOVAL INHIBIT SOLENOID CIRCUIT

|

-

Disconnect Selector Lever Assembly C3531

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C250-3

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

| Yes

|

INSTALL a new selector lever (includes Brake Shift Interlock Actuator (BSIA)).

REFER to:

Selector Lever Assembly

(307-05 Automatic Transmission External Controls, Removal and Installation).

|

|

The Ignition Key Can Be Turned to the OFF Position When the Selector Lever is Not in PARK

Refer to Wiring Diagrams Cell 37 for schematic and connector information.

Normal Operation and Fault Conditions

The key removal inhibit solenoid (part of the ignition switch) receives battery voltage from

fuse 18 (5A). When the selector lever is moved out of the PARK position, the Brake Shift Interlock Actuator (BSIA) (part

of the selector lever) closes, providing a ground circuit to the key removal inhibit solenoid. The key removal inhibit solenoid

activates and prevents the ignition lock cylinder from being turned to the OFF position and the key from being removed.

Possible Causes

-

Wiring, terminals or connectors

-

Key removal inhibit solenoid (part of the ignition switch)

-

Brake Shift Interlock Actuator (BSIA) (part of the selector lever)

PINPOINT TEST G : THE IGNITION KEY CAN BE TURNED TO THE OFF POSITION WHEN THE SELECTOR LEVER IS NOT IN PARK

| G1

CHECK THE KEY INHIBIT SOLENOID CIRCUIT FOR GROUND

|

-

Disconnect Ignition Switch C250

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C250-3

|

|

Ground

|

Is the resistance less than 3 ohms?

| Yes

|

INSTALL a new ignition switch (includes key inhibit solenoid).

REFER to:

Ignition Switch

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

|

| G2

CHECK THE KEY INHIBIT SOLENOID CIRCUIT FOR AN OPEN

|

-

Disconnect Selector Lever Assembly C3531

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C250-3

|

|

C3531-10

|

Is the resistance less than 3 ohms?

|

| G3

CHECK THE SELECTOR LEVER ASSEMBLY GROUND CIRCUIT FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C3531-11

|

|

Ground

|

Is the resistance less than 3 ohms?

| Yes

|

INSTALL a new selector lever assembly (includes Brake Shift Interlock Actuator (BSIA)).

REFER to:

Selector Lever Assembly

(307-05 Automatic Transmission External Controls, Removal and Installation).

|

|

B11D9:16

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

The

continuously monitors input voltage for correct operation. If voltage outside of defined limits is detected by the

, the applicable

sets.

B11D9:16 can set if the vehicle battery has been discharged. The vehicle battery may become discharged due to excessive load(s)

on the charging system from aftermarket accessories or if the vehicle has been left unattended with the accessories on.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

B11D9:16

|

Vehicle Battery: Circuit Below Threshold

|

This

sets in continuous memory if the

detects battery voltage below 8 volts on the battery voltage supply circuit.

|

Possible Causes

-

Battery

-

Wiring, terminals or connectors

-

Fuse

-

Charging system

-

Visual Inspection and Diagnostic Pre-checks

-

Make sure the vehicle battery terminals and cables are free of any corrosion and other contaminates.

-

Make sure the vehicle battery terminals are tightened to their correct torque specifications.

-

Inspect

fuse 13 (7.5A).

PINPOINT TEST H : B11D9:16

| H1

CHECK FOR SCCM (STEERING COLUMN CONTROL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self Test.

-

Enter the following diagnostic mode on the diagnostic scan tool:

Clear Diagnostic Trouble Codes (DTCs).

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self Test.

Is

B119D:16 still present?

| No

|

The system is operating normally at this time. The

may have been set previously during battery charging or while jump starting the vehicle.

|

|

| H2

CHECK FOR CHARGING SYSTEM DIAGNOSTIC TROUBLE CODES (DTCS) IN THE PCM (POWERTRAIN CONTROL MODULE)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self Test.

-

Record all Continuous Memory Diagnostic Trouble Codes (CMDTCs) from the

.

Are any charging system Diagnostic Trouble Codes (DTCs) present in the PCM?

|

| H3

CHECK THE BATTERY CONDITION AND STATE OF CHARGE

|

-

Carry out the Battery Condition Test.

REFER to:

Battery

(414-01 Battery, Mounting and Cables, Diagnosis and Testing).

Is the battery OK?

| No

|

CHARGE the battery and REPEAT the battery condition test. If the battery does not pass the battery condition test, INSTALL

a new battery.

REFER to:

Battery

(414-01 Battery, Mounting and Cables, Removal and Installation).

|

|

| H4

CHECK THE SCCM (STEERING COLUMN CONTROL MODULE)

VOLTAGE SUPPLY

|

-

Measure and record:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

|

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2414A-7

|

|

Ground

|

Is the voltage within 0.2 volt of the recorded battery voltage?

| No

|

VERIFY

fuse 13 (7.5A) is OK. If OK, REPAIR the affected circuit. If not OK, REFER to the Wiring Diagrams manual to identify the

possible causes of the circuit short.

|

|

| H5

CHECK THE SCCM (STEERING COLUMN CONTROL MODULE)

GROUND CIRCUIT

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2414A-5

|

|

Ground

|

Is the resistance less than 3 ohms?

| Yes

|

CONNECT the battery negative cable. GO to

H6

|

| No

|

REPAIR the circuit. CONNECT the battery negative cable.

|

|

| H6

CHECK FOR CORRECT SCCM (STEERING COLUMN CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect the

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Steering Column Control Module (SCCM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

B11D9:17

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

The

continuously monitors input voltage for correct operation. If voltage outside of defined limits is detected by the

, the applicable

sets.

B11D9:17 can set if the vehicle has been recently jump started or the vehicle battery has been recently charged.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

B11D9:17

|

Vehicle Battery: Circuit Above Threshold

|

This

sets in continuous memory if the

detects battery voltage above 19 volts on the battery voltage supply circuit.

|

Possible Causes

-

Wiring, terminals or connectors

-

Charging system

-

PINPOINT TEST I : B11D9:17

| I1

CHECK FOR HIGH BATTERY VOLTAGE AND/OR CHARGING SYSTEM DTC (DIAGNOSTIC TROUBLE CODE)

IN THE PCM (POWERTRAIN CONTROL MODULE)

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self Test.

-

Record all

Continuous Memory Diagnostic Trouble Codes (CMDTCs).

Are any high battery voltage and/or charging system Diagnostic Trouble Codes (DTCs) present in the

?

|

| I2

CHECK THE BATTERY VOLTAGE

|

-

Turn off all interior/exterior lights and accessories.

-

For non-

, start and run the engine at approximately 2,000 rpm for 3 minutes while monitoring the battery voltage.

Does the battery voltage rise to 16.5 volts or higher?

| Yes

|

DIAGNOSE the overcharging condition.

REFER to:

Charging System

(414-00 Charging System - General Information, Diagnosis and Testing).

|

|

| I3

RECHECK FOR SCCM (STEERING COLUMN CONTROL MODULE)

DTC (DIAGNOSTIC TROUBLE CODE)

B119D:17

|

-

Enter the following diagnostic mode on the diagnostic scan tool:

Self Test.

-

Clear the

Diagnostic Trouble Codes (DTCs) and repeat the self-test.

Is

B11D9:17 present in the

?

| No

|

The system is operating normally at this time. The

may have been set previously during battery charging or while jump starting the vehicle.

|

|

| I4

CHECK FOR CORRECT SCCM (STEERING COLUMN CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect the

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

REFER to:

Steering Column Control Module (SCCM)

(211-05 Steering Wheel and Column Electrical Components, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

B1310:12

Refer to Wiring Diagrams Cell 13 for schematic and connector information.

Normal Operation and Fault Conditions

When the ignition is placed in RUN mode, the

provides a ground for the coil (control) side of the run/start relay located in the

. The

monitors the run/start relay control circuit and sets a

if the circuit is shorted to voltage.

Fault Trigger Conditions

|

|

Description

|

Fault Trigger Conditions

|

|

B1310:12

|

Run/Start Control: Circuit Short to Battery

|

When this

sets, the control side of the run/start relay is disabled via the Field Effect Transistor (FET). Once the condition that

caused the

to set is repaired, the

must pass a self-test in order for the

to clear and the system to resume normal operation.

|

Possible Causes

-

Wiring, terminals or connectors

-

run/start relay

-

PINPOINT TEST J : B1310:12

| J1

CHECK THE BJB (BATTERY JUNCTION BOX)

RUN/START RELAY

|

-

Remove the

run/start relay.

-

Carry out the appropriate relay component test.

Refer to Wiring Diagrams Cell 149 for schematic and connector information.

Is the relay OK?

| No

|

INSTALL a new

run/start relay.

|

|

| J2

CHECK THE RUN/START RELAY CONTROL CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C2280C-25

|

|

Ground

|

Is any voltage present?

|

| J3

CHECK FOR CORRECT BCM (BODY CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals - clean module pins)

-

damaged or bent pins - install new terminals/pins

-

pushed-out pins - install new pins as necessary

-

Reconnect the

connectors and all other previously disconnected connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

REFER to:

Body Control Module (BCM)

(419-10 Multifunction Electronic Modules, Removal and Installation).

.

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

Copyright © Ford Motor Company

CFUSE-18 (5A)

CFUSE-18 (5A)

BJB run/start relay socket, Pin 2

BJB run/start relay socket, Pin 2