| 412-00 Climate Control System - General Information

|

2013 - 2014 Fusion

|

| Diagnosis and Testing

|

Procedure revision date:

07/10/2013

|

Climate Control System - Vehicles With: Dual Automatic Temperature Control (DATC)

DTC Chart: Front Controls Interface Module (FCIM) - Dual Automatic Temperature Control (DATC)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. For information

about these practices,

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Network Diagnostic Trouble Codes (DTCs) (U-codes) are often a result of intermittent concerns such as damaged wiring or low

battery voltage occurrences. Additionally, vehicle repair procedures, such as module reprogramming, often set network Diagnostic

Trouble Codes (DTCs). Replacing a module to resolve a network

is unlikely to resolve the concern. To prevent repeat network

concerns, inspect all network wiring, especially connectors. Test the vehicle battery.

REFER to:

Battery

(414-01 Battery, Mounting and Cables, Diagnosis and Testing).

- Dual Automatic Temperature Control (DATC)

CHART

|

DTC

|

Description

|

Action

|

|

B105A:12

|

Cabin Temperature Sensor Fan: Circuit Short To Battery

|

GO to Pinpoint Test N

|

|

B105A:14

|

Cabin Temperature Sensor Fan: Circuit Short To Ground or Open

|

GO to Pinpoint Test N

|

|

B1081:07

|

Left Temperature Damper Motor: Mechanical Failure

|

INSPECT for a binding or a damaged linkage or door. REPAIR as necessary. If no condition is found, INSTALL a new driver side

temperature door actuator.

REFER to:

Driver Side Temperature Door Actuator

(412-00 Climate Control System - General Information, Removal and Installation).

.

|

|

B1081:11

|

Left Temperature Damper Motor: Circuit Short To Ground

|

GO to Pinpoint Test I

|

|

B1081:12

|

Left Temperature Damper Motor: Circuit Short To Battery

|

GO to Pinpoint Test I

|

|

B1081:13

|

Left Temperature Damper Motor: Circuit Open

|

GO to Pinpoint Test I

|

|

B1082:07

|

Right Temperature Damper Motor: Mechanical Failure

|

INSPECT for a binding or a damaged linkage or door. REPAIR as necessary. If no condition is found, INSTALL a new passenger

side temperature door actuator.

REFER to:

Passenger Side Temperature Door Actuator

(412-00 Climate Control System - General Information, Removal and Installation).

|

|

B1082:11

|

Right Temperature Damper Motor: Circuit Short To Ground

|

GO to Pinpoint Test J

|

|

B1082:12

|

Right Temperature Damper Motor: Circuit Short To Battery

|

GO to Pinpoint Test J

|

|

B1082:13

|

Right Temperature Damper Motor: Circuit Open

|

GO to Pinpoint Test J

|

|

B1083:07

|

Recirculation Damper Motor: Mechanical Failure

|

INSPECT for a binding or a damaged linkage or door. REPAIR as necessary. If no condition is found, INSTALL a new air inlet

mode door actuator.

REFER to:

Air Inlet Door Actuator

(412-00 Climate Control System - General Information, Removal and Installation).

|

|

B1083:11

|

Recirculation Damper Motor: Circuit Short To Ground

|

GO to Pinpoint Test D

|

|

B1083:12

|

Recirculation Damper Motor: Circuit Short To Battery

|

GO to Pinpoint Test D

|

|

B1083:13

|

Recirculation Damper Motor: Circuit Open

|

GO to Pinpoint Test D

|

|

B1086:07

|

Air Distribution Damper Motor: Mechanical Failure

|

INSPECT for a binding or a damaged linkage or door. REPAIR as necessary. If no condition is found, INSTALL a new air distribution

door actuator.

REFER to:

Air Distribution Door Actuator

(412-00 Climate Control System - General Information, Removal and Installation).

|

|

B1086:11

|

Air Distribution Damper Motor: Circuit Short To Ground

|

GO to Pinpoint Test E

|

|

B1086:12

|

Air Distribution Damper Motor: Circuit Short To Battery

|

GO to Pinpoint Test E

|

|

B1086:13

|

Air Distribution Damper Motor: Circuit Open

|

GO to Pinpoint Test E

|

|

B10AF:11

|

Blower Fan Relay: Circuit Short To Ground

|

GO to Pinpoint Test K

|

|

B10AF:12

|

Blower Fan Relay: Circuit Short To Battery

|

GO to Pinpoint Test L

|

|

B10AF:13

|

Blower Fan Relay: Circuit Open

|

GO to Pinpoint Test L

|

|

B10B3:11

|

Right Panel Air Discharge Temperature: Circuit Short To Ground

|

GO to Pinpoint Test M

|

|

B10B3:15

|

Right Panel Air Discharge Temperature: Circuit Short To Battery or Open

|

GO to Pinpoint Test M

|

|

B10B4:11

|

Right Floor Air Discharge Temperature: Circuit Short To Ground

|

GO to Pinpoint Test M

|

|

B10B4:15

|

Right Floor Air Discharge Temperature: Circuit Short To Battery or Open

|

GO to Pinpoint Test M

|

|

B10B5:11

|

Left Panel Air Discharge Temperature: Circuit Short To Ground

|

GO to Pinpoint Test M

|

|

B10B5:15

|

Left Panel Air Discharge Temperature: Circuit Short To Battery or Open

|

GO to Pinpoint Test M

|

|

B10B6:11

|

Left Floor Air Discharge Temperature: Circuit Short To Ground

|

GO to Pinpoint Test M

|

|

B10B6:15

|

Left Floor Air Discharge Temperature: Circuit Short To Ground

|

GO to Pinpoint Test M

|

|

B10B8:63

|

Push Buttons: Circuit / Component Protection Time-Out

|

-

Buttons held too long may set this

. ATTEMPT to clean buttons. CLEAR the Diagnostic Trouble Codes (DTCs) and REPEAT the self-test. If the

does not return, IGNORE the

and CONTINUE diagnosing other Diagnostic Trouble Codes (DTCs) or symptoms. If the

returns, INSTALL a new

.

-

For vehicles equipped with Sony® Audio System,

REFER to:

Information and Entertainment System

(415-00C Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Sony Audio System, Diagnosis and Testing).

-

For vehicles equipped with Touchscreen Display,

REFER to:

Information and Entertainment System

(415-00B Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Touchscreen Display, Diagnosis and Testing).

-

For all other audio systems,

REFER to:

Information and Entertainment System

(415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Diagnosis and Testing).

|

|

B10B9:12

|

Blower Control: Circuit Short To Battery

|

|

|

B10B9:14

|

Blower Control: Circuit Short To Ground or Open

|

|

|

B11E5:11

|

Left HVAC Damper Position Sensor: Circuit Short To Ground

|

GO to Pinpoint Test I

|

|

B11E5:15

|

Left HVAC Damper Position Sensor: Circuit Short To Battery or Open

|

GO to Pinpoint Test I

|

|

B11E6:11

|

Right HVAC Damper Position Sensor: Circuit Short To Ground

|

GO to Pinpoint Test J

|

|

B11E6:15

|

Right HVAC Damper Position Sensor: Circuit Short To Battery or Open

|

GO to Pinpoint Test J

|

|

B11E7:11

|

Air Distribution Damper Position Sensor: Circuit Short To Ground

|

GO to Pinpoint Test E

|

|

B11E7:15

|

Air Distribution Damper Position Sensor: Circuit Short To Battery or Open

|

GO to Pinpoint Test E

|

|

B11F0:11

|

Air Intake Damper Position Sensor: Circuit Short To Ground

|

GO to Pinpoint Test D

|

|

B11F0:15

|

Air Intake Damper Position Sensor: Circuit Short To Battery or Open

|

GO to Pinpoint Test D

|

|

B1A61:11

|

Cabin Temperature Sensor: Circuit Short To Ground

|

GO to Pinpoint Test N

|

|

B1A61:15

|

Cabin Temperature Sensor: Circuit Short To Battery or Open

|

GO to Pinpoint Test N

|

|

B1A63:11

|

Right Solar Sensor: Circuit Short To Ground

|

GO to Pinpoint Test O

|

|

B1A63:15

|

Right Solar Sensor: Circuit Short To Battery or Open

|

GO to Pinpoint Test O

|

|

B1A64:11

|

Left Solar Sensor: Circuit Short To Ground

|

GO to Pinpoint Test O

|

|

B1A64:15

|

Left Solar Sensor: Circuit Short To Battery or Open

|

GO to Pinpoint Test O

|

|

B1A69:11

|

Humidity Sensor: Circuit Short To Ground

|

GO to Pinpoint Test N

|

|

B1A69:15

|

Humidity Sensor: Circuit Short To Battery or Open

|

GO to Pinpoint Test N

|

|

B1B71:11

|

Evaporator Temperature Sensor: Circuit Short To Ground

|

GO to Pinpoint Test P

|

|

B1B71:15

|

Evaporator Temperature Sensor: Circuit Short To Battery or Open

|

GO to Pinpoint Test P

|

|

C1B14:11

|

Sensor Supply Voltage A: Circuit Short To Ground

|

GO to Pinpoint Test Q

|

|

C1B14:12

|

Sensor Supply Voltage A: Circuit Short To Battery

|

GO to Pinpoint Test Q

|

|

All Other

Diagnostic Trouble Codes (DTCs) not listed in this chart

|

—

|

-

For vehicles equipped with Sony® Audio System,

REFER to:

Information and Entertainment System

(415-00C Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Sony Audio System, Diagnosis and Testing).

-

For vehicles equipped with Touchscreen Display,

REFER to:

Information and Entertainment System

(415-00B Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Touchscreen Display, Diagnosis and Testing).

-

For all other audio systems,

REFER to:

Information and Entertainment System

(415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Diagnosis and Testing).

|

DTC Chart: Powertrain Control Module (PCM)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. For information

about these practices,

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Powertrain Control Module (PCM) DTC Chart

Symptom Chart(s)

Symptom Chart: Climate Control - Dual Automatic Temperature Control (DATC)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. For information

about these practices,

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Symptom Chart

|

Condition

|

Possible Sources

|

Actions

|

|

A module does not communicate with the diagnostic scan tool

|

-

Fuse(s)

-

Wiring, terminals or connectors

-

|

REFER to:

Communications Network

(418-00 Module Communications Network, Diagnosis and Testing).

|

|

Unable To Duplicate The Customer Concern And No Diagnostic Trouble Codes (DTCs) Present

|

Refer to Pinpoint Test

|

GO to Pinpoint Test C

|

|

functions are inoperative/do not operate correctly from touchscreen only

|

|

REFER to:

Information and Entertainment System

(415-00B Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Touchscreen Display, Diagnosis and Testing).

|

|

Reduced outlet airflow

|

Refer to Pinpoint Test

|

GO to Pinpoint Test H

|

|

The air inlet door is inoperative

|

Refer to Pinpoint Test

|

GO to Pinpoint Test D

|

|

Incorrect or erratic direction of airflow from outlets

|

Refer to Pinpoint Test

|

GO to Pinpoint Test E

|

|

Insufficient, erratic or no heat

|

Refer to Pinpoint Test

|

GO to Pinpoint Test F

|

|

Insufficient heat in Auto Start-Stop mode only

|

Refer to Pinpoint Test

|

GO to Pinpoint Test R

|

|

The

is inoperative

|

Refer to Pinpoint Test

|

GO to Pinpoint Test G

|

|

The

is always on —

mode always commanded ON

|

Refer to Pinpoint Test

|

GO to Pinpoint Test H

|

|

Temperature control is inoperative/does not operate correctly —

|

Refer to Pinpoint Test

|

GO to Pinpoint Test I

|

|

Temperature control is inoperative/does not operate correctly —

|

Refer to Pinpoint Test

|

GO to Pinpoint Test J

|

|

The blower motor is inoperative

|

Refer to Pinpoint Test

|

GO to Pinpoint Test K

|

|

The blower motor does not operate correctly

|

Refer to Pinpoint Test

|

GO to Pinpoint Test L

|

|

Insufficient

cooling

|

Improper refrigerant level

|

CARRY OUT the refrigerant system tests.

REFER to:

Refrigerant System Tests

(412-00 Climate Control System - General Information, General Procedures).

If OK, DIAGNOSE for a temperature door actuator not operating correctly.

|

|

Temperature door actuator

|

|

|

pressure relief valve discharging

|

pressure relief valve

|

-

CHECK the high side system pressure.

REFER to:

Specifications

(412-00 Climate Control System - General Information, Specifications).

If the pressure is below the

pressure relief valve open pressure, INSTALL a new

Compressor.

-

For 1.5L,

REFER to:

Air Conditioning (A/C) Compressor - 1.5L EcoBoost (118kW/160PS)

(412-00 Climate Control System - General Information, Removal and Installation).

-

For 1.6L,

REFER to:

Air Conditioning (A/C) Compressor - 1.6L EcoBoost (132kW/180PS) - Sigma

(412-00 Climate Control System - General Information, Removal and Installation).

-

For 2.0L,

REFER to:

Air Conditioning (A/C) Compressor - 2.0L EcoBoost (184kW/250PS) - MI4

(412-00 Climate Control System - General Information, Removal and Installation).

-

For 2.5L,

REFER to:

Air Conditioning (A/C) Compressor - 2.5L Duratec (125kW/170PS)

(412-00 Climate Control System - General Information, Removal and Installation).

|

|

High system pressure

|

CHECK the high side system pressure.

REFER to:

Specifications

(412-00 Climate Control System - General Information, Specifications).

If the system pressure is above the

pressure relief valve open pressure, REPAIR the

system for a restriction.

|

Symptom Chart: Noise, Vibration, and Harshness (NVH)

Diagnostics in this manual assume a certain skill level and knowledge of Ford-specific diagnostic practices. For information

about these practices,

REFER to:

Diagnostic Methods

(100-00 General Information, Description and Operation).

Symptom Chart

|

Condition

|

Possible Sources

|

Actions

|

|

Noisy

compressor

|

compressor bearing worn

|

|

|

Excessive hissing from the plenum when the

is on

|

Incorrect

refrigerant level

|

CHECK the

refrigerant level

REFER to:

Refrigerant System Tests

(412-00 Climate Control System - General Information, General Procedures).

|

Pinpoint Test(s)

P0532, P0533

Refer to Wiring Diagrams Cell 55 for schematic and connector information.

Normal operation and Fault Conditions

The

pressure transducer receives a ground from the

. A 5-volt reference voltage is supplied to the

pressure transducer from the

. The

pressure transducer then sends a voltage to the

to indicate the

pressure.

DTC Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

P0532

|

A/C Refrigerant Pressure Sensor "A" Circuit Low

|

The

pressure transducer inputs a feedback voltage to the

. This

sets if the feedback voltage is less than 0.26 volt for at least 2 seconds and the ambient air temperature is greater than

0°C (32°F).

|

|

P0533

|

A/C Refrigerant Pressure Sensor "A" Circuit High

|

The

pressure transducer inputs a feedback voltage to the

. This

sets if the feedback voltage is greater than 4.95 volts for at least 2 seconds and the ambient air temperature is greater

than 0°C (32°F).

|

Possible Sources

-

Wiring, terminals or connectors

-

pressure transducer

-

Visual Inspection and Diagnostic Pre-checks

-

Inspect for loose or corroded

and

pressure transducer connections.

PINPOINT TEST A : P0532, P0533

| NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

|

| A1

COMPARE THE PCM (POWERTRAIN CONTROL MODULE)

PRESSURE SENSOR (ACP_PRESS) PID (PARAMETER IDENTIFICATION)

WITH THE MANIFOLD GAUGE SET READINGS

|

-

Allow the

system to stabilize to the outside ambient temperature.

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

-

With the manifold gauge set connected, compare the pressure readings of the manifold gauge set and the

ACP_PRESS

.

Are the pressure values of the manifold gauge set and the

within +/-15 psi?

| Yes

|

IGNORE the Diagnostic Trouble Codes (DTCs). REFER to the Symptom Chart in this section.

|

|

| A2

CHECK THE PCM (POWERTRAIN CONTROL MODULE)

REFERENCE VOLTAGE CIRCUIT

|

-

Disconnect

pressure transducer C1260

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-3

|

|

Ground

|

Is the voltage between 4.7 and 5.1 volts?

| No

|

If the voltage is less than 4.7 volts, GO to

A3

If the voltage is greater than 5.1 volts, REPAIR the circuit for a short to voltage.

|

|

| A3

CHECK THE REFERENCE VOLTAGE CIRCUIT FOR A SHORT TO GROUND

|

-

Disconnect

1.5L C1915B, 1.6L C1232B, 2.0L C1381B or 2.5L C1551B

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-3

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| A4

CHECK THE REFERENCE VOLTAGE CIRCUIT FOR AN OPEN

|

-

Measure:

1.5L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-3

|

|

C1915B-11

|

1.6L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-3

|

|

C1232B-11

|

2.0L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-3

|

|

C1381B-11

|

2.5L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-3

|

|

C1551B-52

|

Is the resistance less than 3 ohms?

|

| A5

CHECK THE SIGNAL RETURN CIRCUIT

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-1

|

|

C1260-3

|

Is the voltage between 4.7 and 5.1 volts?

| Yes

|

If diagnosing

P0532, GO to

A8

If diagnosing

P0533, GO to

A11

|

|

| A6

CHECK THE SIGNAL RETURN CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-1

|

|

Ground

|

Is any voltage present?

|

| A7

CHECK THE SIGNAL RETURN CIRCUIT FOR AN OPEN

|

-

Disconnect

1.5L C1915B, 1.6L C1232B, 2.0L C1381B or 2.5L C1551B

.

-

Measure:

1.5L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-1

|

|

C1915B-18

|

1.6L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-1

|

|

C1232B-18

|

2.0L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-1

|

|

C1381B-18

|

2.5L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-1

|

|

C1551B-56

|

Is the resistance less than 3 ohms?

|

| A8

CHECK THE PCM (POWERTRAIN CONTROL MODULE)

A/C (AIR CONDITIONING)

PRESSURE SENSOR (ACP_V) PID (PARAMETER IDENTIFICATION)

WITH THE A/C (AIR CONDITIONING)

PRESSURE TRANSDUCER SHORTED

|

-

Connect a fused jumper wire between:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-2

|

|

C1260-3

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

-

Monitor the ACP_V

voltage.

Does the

voltage display between 4.7 and 5.1 volts?

| No

|

REMOVE the fused jumper wire. GO to

A9

|

|

| A9

CHECK THE A/C (AIR CONDITIONING)

PRESSURE TRANSDUCER FEEDBACK CIRCUIT FOR A SHORT TO THE SIGNAL RETURN CIRCUIT

|

-

Disconnect

1.5L C1915B, 1.6L C1232B, 2.0L C1381B or 2.5L C1551B

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-2

|

|

C1260-1

|

Is the resistance greater than 10,000 ohms?

|

| A10

CHECK THE A/C (AIR CONDITIONING)

PRESSURE TRANSDUCER FEEDBACK CIRCUIT FOR AN OPEN

|

-

Measure:

1.5L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-2

|

|

C1915B-52

|

1.6L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-2

|

|

C1232B-52

|

2.0L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-2

|

|

C1381B-52

|

2.5L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-2

|

|

C1551B-31

|

Is the resistance less than 3 ohms?

|

| A11

CHECK THE A/C (AIR CONDITIONING)

PRESSURE TRANSDUCER

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

-

Monitor the

pressure sensor (ACP_V)

voltage.

Does the

voltage display 0 volts?

|

| A12

CHECK THE A/C (AIR CONDITIONING)

PRESSURE TRANSDUCER FEEDBACK CIRCUIT FOR VOLTAGE

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-2

|

|

Ground

|

Is any voltage present?

|

| A13

CHECK THE A/C (AIR CONDITIONING)

PRESSURE TRANSDUCER FEEDBACK CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Disconnect

1.5L C1915B, 1.6L C1232B, 2.0L C1381B or 2.5L C1551B

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C1260-2

|

|

Ground

|

Is any voltage present?

| No

|

REPAIR feedback circuit for a short to signal return circuit.

|

|

| A14

CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all

connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Connect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

For 1.5L,

REFER to:

Powertrain Control Module (PCM)

(303-14A Electronic Engine Controls - 1.5L EcoBoost (118kW/160PS), Removal and Installation).

For 1.6L,

REFER to:

Powertrain Control Module (PCM)

(303-14B Electronic Engine Controls - 1.6L EcoBoost (132kW/180PS) - Sigma, Removal and Installation).

For 2.0L,

REFER to:

Powertrain Control Module (PCM)

(303-14C Electronic Engine Controls - 2.0L EcoBoost (184kW/250PS) - MI4, Removal and Installation).

For 2.5L,

REFER to:

Powertrain Control Module (PCM)

(303-14D Electronic Engine Controls - 2.5L Duratec (125kW/170PS), Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. ADDRESS

the root cause of any connector or pin issues.

|

|

P0645

Refer to Wiring Diagrams Cell 55 for schematic and connector information.

Normal Operation and Fault Conditions

Voltage is provided to the

clutch relay coil. When

is requested and

line pressures allow, a ground is provided to the

clutch relay coil from the

, energizing the

clutch relay.

DTC Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

P0645

|

A/C Clutch Relay Control Circuit

|

The

sets when the

grounds the relay circuit and more voltage than expected is detected on the relay circuit. The

also sets when the relay circuit is off and no voltage is detected on the relay circuit. The

expects to detect voltage coming through the relay coil to the relay circuit when it is not grounding it.

|

Possible Sources

-

Wiring, terminals or connectors

-

clutch relay

-

Visual Inspection and Diagnostic Pre-checks

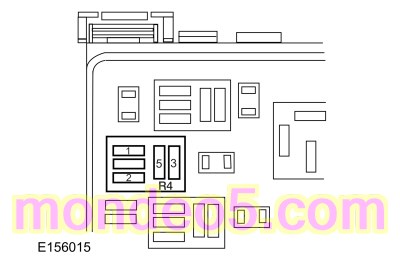

PINPOINT TEST B : P0645

| NOTICE:

Use the correct probe adapter(s) from the Flex Probe Kit when taking measurements. Failure to use the correct probe adapter(s)

may damage the connector.

|

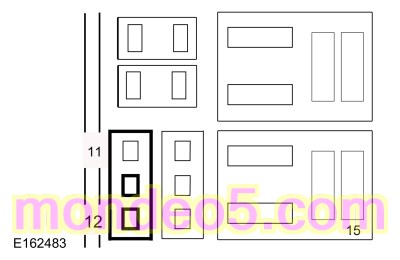

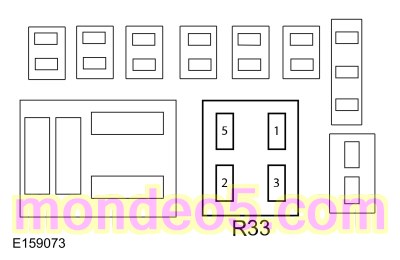

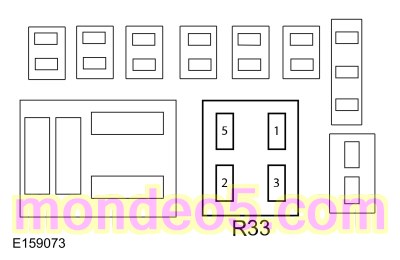

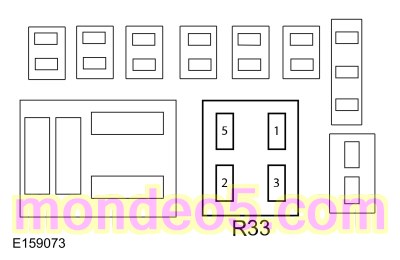

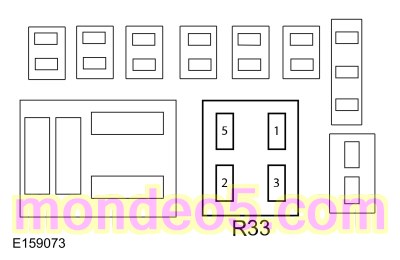

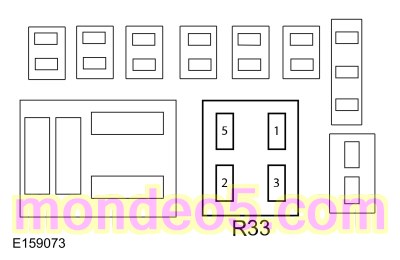

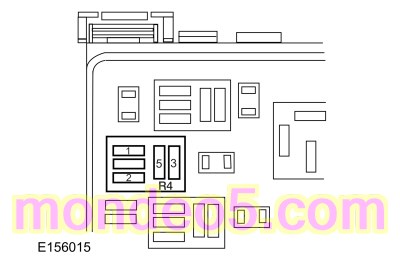

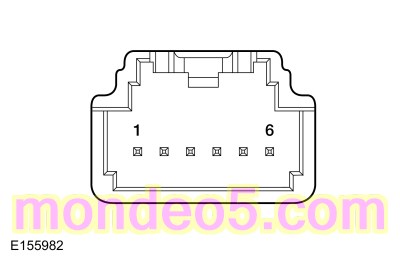

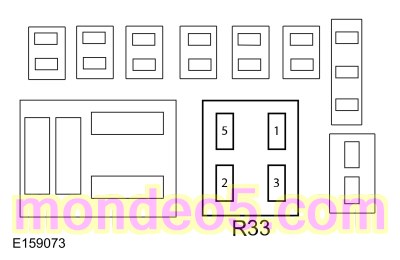

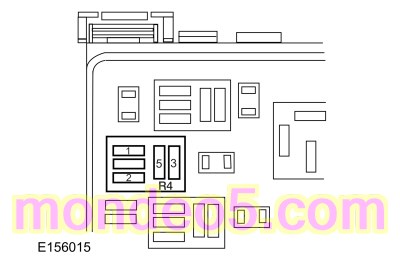

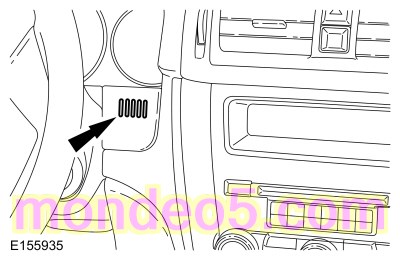

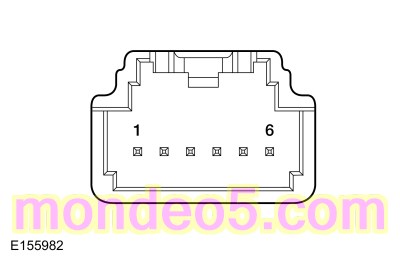

| B1

CHECK THE VOLTAGE TO THE A/C (AIR CONDITIONING)

CLUTCH RELAY COIL VOLTAGE SUPPLY CIRCUIT FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

Pin 2

Pin 2

|

|

Ground

|

Is the voltage greater than 11 volts?

|

| B2

SUBSTITUTE A KNOWN GOOD RELAY FOR THE A/C (AIR CONDITIONING)

CLUTCH RELAY

|

-

Substitute a known good relay for the

clutch relay.

-

Using a diagnostic scan tool, perform

self-test.

Is

P0645:00 still present?

| No

|

INSTALL a new

clutch relay.

|

|

| B3

CHECK THE A/C (AIR CONDITIONING)

CLUTCH RELAY CONTROL CIRCUIT FOR A SHORT TO VOLTAGE

|

-

Disconnect

1.5L C1915B, 1.6L C1232B, 2.0L C1381B or 2.5L C1551B

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

Pin 1

Pin 1

|

|

Ground

|

Is any voltage present?

|

| B4

CHECK THE A/C (AIR CONDITIONING)

CLUTCH RELAY CONTROL CIRCUIT FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

Pin 1

Pin 1

|

|

Ground

|

Is the resistance greater than 10,000 ohms?

|

| B5

CHECK THE A/C (AIR CONDITIONING)

CLUTCH RELAY CONTROL CIRCUIT FOR AN OPEN

|

-

Measure:

1.5L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

Pin 1

Pin 1

|

|

C1915B-2

|

1.6L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

Pin 1

Pin 1

|

|

C1232B-2

|

2.0L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

Pin 1

Pin 1

|

|

C1381B-2

|

2.5L

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

Pin 1

Pin 1

|

|

C1551B-12

|

Is the resistance less than 3 ohms?

|

| B6

CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect all the

connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Connect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

For 1.5L,

REFER to:

Powertrain Control Module (PCM)

(303-14A Electronic Engine Controls - 1.5L EcoBoost (118kW/160PS), Removal and Installation).

For 1.6L,

REFER to:

Powertrain Control Module (PCM)

(303-14B Electronic Engine Controls - 1.6L EcoBoost (132kW/180PS) - Sigma, Removal and Installation).

For 2.0L,

REFER to:

Powertrain Control Module (PCM)

(303-14C Electronic Engine Controls - 2.0L EcoBoost (184kW/250PS) - MI4, Removal and Installation).

For 2.5L,

REFER to:

Powertrain Control Module (PCM)

(303-14D Electronic Engine Controls - 2.5L Duratec (125kW/170PS), Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. ADDRESS

the root cause of any connector or pin issues.

|

|

Unable To Duplicate The Customer Concern And No Diagnostic Trouble Codes (DTCs) Present

This diagnostic procedure tests the functions of the

system and identifies the correct

symptom pinpoint test.

Normal Operation and Fault Conditions

System Operation

REFER to:

Climate Control System - Vehicles With: Dual Automatic Temperature Control (DATC) - System Operation and Component Description

(412-00 Climate Control System - General Information, Description and Operation).

PINPOINT TEST C : UNABLE TO DUPLICATE THE CUSTOMER CONCERN AND NO DIAGNOSTIC TROUBLE CODES (DTCS) PRESENT

| C1

CHECK THE PCM (POWERTRAIN CONTROL MODULE)

FOR DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Using a scan tool, perform

self-test.

Are any climate control related Diagnostic Trouble Codes (DTCs) present?

| Yes

|

REFER to the

chart in this section.

|

|

| C2

CHECK THE FCIM (FRONT CONTROLS INTERFACE MODULE)

FOR DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Using a diagnostic scan tool, perform

self-test.

Are any Diagnostic Trouble Codes (DTCs) present?

| Yes

|

REFER to the

chart in this section.

|

|

| C3

CHECK THE BLOWER MOTOR OPERATION

|

-

Observe blower motor operation and select each blower motor speed.

Does the blower motor operate in all ranges?

|

| C4

CHECK AIRFLOW OPERATION

|

-

Select the highest blower motor setting.

-

While observing the airflow, select each of the airflow positions (panel, panel/floor, floor, floor/defrost, defrost).

Is the airflow directed to the correct outlets?

|

| C5

VERIFY TEMPERATURE CONTROL OPERATION

|

-

Start the vehicle and allow it to reach normal operating temperature.

-

With the

off, select panel mode.

-

Change the driver and passenger temperature settings from the coldest to the warmest and back to the coldest.

Does the temperature change between very warm to cool?

|

| C6

VERIFY THE AIR CONDITIONING COMPRESSOR DOES NOT ENGAGE WITH A/C (AIR CONDITIONING)

OFF

|

-

With the engine running and the

off, select panel mode.

-

Select the coldest temperature setting.

Is the outlet temperature close to ambient air temperature?

|

| C7

VERIFY THE A/C (AIR CONDITIONING)

COMPRESSOR IS OPERATIONAL IN THE A/C (AIR CONDITIONING)

MODE

|

-

Make sure the ambient air temperature is above 2°C (36°F).

-

With the engine running, select panel mode.

-

Press the

button (indicator on).

Is the

compressor operational when the panel and

button (indicator on) is pressed?

|

| C8

CHECK THE RECIRCULATED AIR OPERATION

|

-

With the engine running, press the recirculated air button (indicator off).

-

Select the highest blower motor setting.

-

Press the recirculated air button (indicator on).

Does the airflow noise increase when the recirculated air mode is selected (indicator on)?

|

| C9

CHECK THE FCIM (FRONT CONTROLS INTERFACE MODULE)

LEFT DISCHARGE FLOOR TEMPERATURE (LDFTEMP) PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view the

Parameter Identifications (PIDs).

Is the temperature coming out of the driver footwell vent similar to the

?

|

| C10

CHECK THE FCIM (FRONT CONTROLS INTERFACE MODULE)

LEFT DISCHARGE PANEL TEMPERATURE (LDPT) PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view the

Parameter Identifications (PIDs).

Is the temperature coming out of the driver side register similar to the

?

|

| C11

CHECK THE FCIM (FRONT CONTROLS INTERFACE MODULE)

DISCHARGE AIR TEMPERATURE RIGHT FLOOR (AIRTEMP_RF) PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view the

Parameter Identifications (PIDs).

Is the temperature coming out of the passenger footwell vent similar to the

?

|

| C12

CHECK THE FCIM (FRONT CONTROLS INTERFACE MODULE)

DISCHARGE AIR TEMPERATURE RIGHT PANEL (AIRTEMP_RP) PID (PARAMETER IDENTIFICATION)

|

-

Using a scan tool view the

Parameter Identifications (PIDs).

Is the temperature coming out of the passenger side register similar to the

?

|

| C13

CHECK THE FCIM (FRONT CONTROLS INTERFACE MODULE)

INTERIOR TEMPERATURE SENSOR (INT_TEMP) PID (PARAMETER IDENTIFICATION)

|

-

Using a scan tool view the

Parameter Identifications (PIDs).

Is the air temperature at the cabin temperature sensor similar to the

?

|

| C14

CHECK THE TOUCHSCREEN CONTROLS OPERATION

|

-

Using the touchscreen controls, select each climate control function.

-

Using the touchscreen controls, select each audio control function.

Do all touchscreen controls operate?

| Yes

|

The system is operating correctly.

|

| No

|

REFER to:

Information and Entertainment System

(415-00B Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Touchscreen Display, Diagnosis and Testing).

|

|

The Air Inlet Blend Door Is Inoperative

Refer to Wiring Diagrams Cell 55 for schematic and connector information.

Normal Operation and Fault Conditions

To rotate the air inlet blend door actuator, the

supplies voltage and ground to the air inlet blend door actuator through the door actuator motor circuits. To reverse the

air inlet blend door actuator rotation, the

reverses the voltage and ground circuits. The air inlet blend door actuator feedback resistors are supplied a ground from

the

by the air inlet blend door actuator return circuits and a 5-volt reference voltage on the air inlet blend door actuator

reference circuits. The

reads the voltage on the air inlet blend door actuator feedback circuits to determine the air inlet blend door actuator position

by the position of the actuator feedback resistor wiper arm.

During an actuator calibration cycle, the

drives the air inlet blend door until the door reaches both internal stops in the

case. If the air inlet mode door is temporarily obstructed or binding during a calibration cycle, the

may interpret this as the actual end of travel for the door. When this condition occurs and the

commands the actuator to its end of travel, the air intake may not be from the expected source.

DTC Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B1083:11

|

Recirculation Damper Motor: Circuit Short To Ground

|

This

sets when the module senses lower than expected voltage on an actuator motor circuit when voltage is applied to drive the

motor, indicating a short to ground.

|

|

B1083:12

|

Recirculation Damper Motor: Circuit Short To Battery

|

This

sets when the module senses higher than expected voltage on the actuator motor circuit when ground is applied to drive the

motor, indicating a short to voltage.

|

|

B1083:13

|

Recirculation Damper Motor: Circuit Open

|

This

sets when the module senses no voltage on the actuator motor circuit when ground is applied to drive the motor, indicating

a open circuit.

|

|

B11F0:11

|

Air Intake Damper Position Sensor: Circuit Short to Ground

|

This

sets when the module senses less than 1 volt on the actuator feedback circuit, indicating a short to ground.

|

|

B11F0:15

|

Air Intake Damper Position Sensor: Circuit Short to Battery or Open

|

This

sets when the module senses greater than 4 volts on the actuator feedback circuit, indicating an open circuit or a short

to voltage.

|

Possible Sources

-

Wiring, terminals or connectors

-

Air inlet blend door actuator

-

Air inlet blend door binding or stuck

-

PINPOINT TEST D : THE AIR INLET BLEND DOOR IS INOPERATIVE

| NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

|

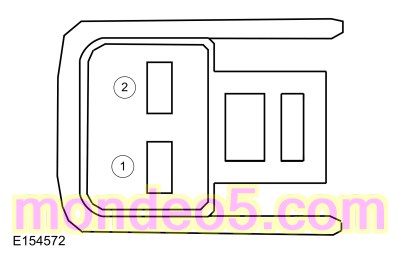

| D1

CHECK THE AIR INLET BLEND DOOR ACTUATOR CIRCUITS FOR A SHORT TO VOLTAGE

|

-

Disconnect Air Inlet Blend Door Actuator C289

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C289-1

|

|

Ground

|

|

C289-2

|

|

Ground

|

|

C289-3

|

|

Ground

|

|

C289-4

|

|

Ground

|

|

C289-6

|

|

Ground

|

Is there any voltage present?

|

| D2

CHECK THE AIR INLET BLEND DOOR ACTUATOR CIRCUITS FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C289-1

|

|

Ground

|

|

C289-2

|

|

Ground

|

|

C289-3

|

|

Ground

|

|

C289-4

|

|

Ground

|

|

C289-6

|

|

Ground

|

Are the resistances greater than 10,000 ohms?

|

| D3

CHECK THE AIR INLET BLEND DOOR ACTUATOR CIRCUITS FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C289-1

|

|

C2402A-24

|

|

C289-2

|

|

C2402A-2

|

|

C289-3

|

|

C2402A-3

|

|

C289-4

|

|

C2402A-16

|

|

C289-6

|

|

C2402A-25

|

Are the resistances less than 3 ohms?

|

| D4

CHECK THE AIR INLET BLEND DOOR ACTUATOR CIRCUITS FOR A SHORT TOGETHER

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C289-1

|

|

C289-2

|

|

C289-1

|

|

C289-3

|

|

C289-1

|

|

C289-4

|

|

C289-1

|

|

C289-6

|

|

C289-2

|

|

C289-3

|

|

C289-2

|

|

C289-4

|

|

C289-2

|

|

C289-6

|

|

C289-3

|

|

C289-4

|

|

C289-3

|

|

C289-6

|

|

C289-4

|

|

C289-6

|

Are the resistances greater than 10,000 ohms?

| Yes

|

INSTALL a new air inlet blend door actuator.

REFER to:

Air Inlet Door Actuator

(412-00 Climate Control System - General Information, Removal and Installation).

TEST the system for normal operation. If the concern is still present, GO to

D5

|

|

| D5

CHECK FOR CORRECT FRONT CONTROLS INTERFACE MODULE OPERATION

|

-

Disconnect and inspect all the

connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Connect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

For vehicles equipped with Sony® Audio System,

REFER to:

Front Controls Interface Module (FCIM)

(415-00C Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Sony Audio System, Removal and Installation).

For vehicles equipped with Touchscreen Display,

REFER to:

Front Controls Interface Module (FCIM)

(415-00B Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Touchscreen Display, Removal and Installation).

For all other audio systems,

REFER to:

Front Controls Interface Module (FCIM)

(415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. ADDRESS

the root cause of any connector or pin issues.

|

|

Incorrect Or Erratic Direction Of Airflow From Outlets

Refer to Wiring Diagrams Cell 55 for schematic and connector information.

Normal Operation and Fault Conditions

To rotate the air distribution door actuator, the

supplies voltage and ground to the air distribution door actuator through the door actuator motor circuits. To reverse the

air distribution door actuator rotation, the

reverses the voltage and ground circuits. The air distribution door actuator feedback resistors are supplied a ground from

the

by the air distribution door actuator return circuits and a 5-volt reference voltage on the air distribution door actuator

reference circuits. The

reads the voltage on the air distribution door actuator feedback circuits to determine the air distribution door actuator

position by the position of the actuator feedback resistor wiper arm.

During an actuator calibration cycle, the

drives the air distribution door until the door reaches both internal stops in the

case. If the air distribution door is temporarily obstructed or binding during a calibration cycle, the

may interpret this as the actual end of travel for the door. When this condition occurs and the

commands the actuator to its end of travel, the airflow may not be from the expected outlets.

DTC Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B1086:11

|

Air Distribution Damper Motor: Circuit Short to Ground

|

This

sets when the module senses no changes in the feedback circuit when motor movement is commanded and no motor electrical Diagnostic

Trouble Codes (DTCs) are present.

|

|

B1086:12

|

Air Distribution Damper Motor: Circuit Short to Battery

|

This

sets when the module senses no changes in the feedback circuit when motor movement is commanded and no motor electrical Diagnostic

Trouble Codes (DTCs) are present.

|

|

B1086:13

|

Air Distribution Damper Motor: Circuit Open

|

This

sets when the module senses no voltage on the actuator motor circuit when ground is applied to drive the motor, indicating

a open circuit.

|

|

B11E7:11

|

Air Distribution Damper Position Sensor: Circuit Short to ground

|

This

sets when the module senses less than 1 volt on the actuator feedback circuit, indicating a short to ground.

|

|

B11E7:15

|

Air Distribution Damper Position Sensor: Circuit Short to Battery or Open

|

This

sets when the module senses greater than 4 volts on the actuator feedback circuit, indicating an open circuit or a short

to voltage.

|

Possible Sources

-

Wiring, terminals or connectors

-

Air distribution door actuator

-

Air distribution door binding or stuck

-

PINPOINT TEST E : INCORRECT OR ERRATIC DIRECTION OF AIRFLOW FROM OUTLETS

| NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

|

| E1

CHECK THE AIR DISTRIBUTION DOOR ACTUATOR CIRCUITS FOR A SHORT TO VOLTAGE

|

-

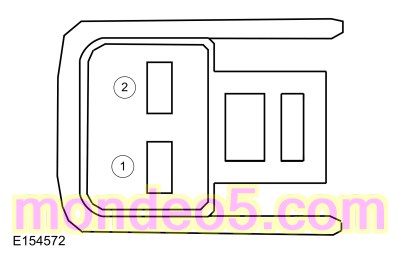

Disconnect Air distribution door actuator C236

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C236-1

|

|

Ground

|

|

C236-2

|

|

Ground

|

|

C236-3

|

|

Ground

|

|

C236-4

|

|

Ground

|

|

C236-6

|

|

Ground

|

Is there any voltage present?

|

| E2

CHECK THE AIR DISTRIBUTION DOOR ACTUATOR CIRCUITS FOR A SHORT TO GROUND

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C236-1

|

|

Ground

|

|

C236-2

|

|

Ground

|

|

C236-3

|

|

Ground

|

|

C236-4

|

|

Ground

|

|

C236-6

|

|

Ground

|

Are the resistances greater than 10,000 ohms?

|

| E3

CHECK THE AIR DISTRIBUTION DOOR ACTUATOR CIRCUITS FOR AN OPEN

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C236-1

|

|

C2402A-20

|

|

C236-2

|

|

C2402A-2

|

|

C236-3

|

|

C2402A-3

|

|

C236-4

|

|

C2402A-22

|

|

C236-6

|

|

C2402A-21

|

Are the resistances less than 3 ohms?

|

| E4

CHECK THE AIR DISTRIBUTION DOOR ACTUATOR CIRCUITS FOR A SHORT TOGETHER

|

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

|

C236-1

|

|

C236-2

|

|

C236-1

|

|

C236-3

|

|

C236-1

|

|

C236-4

|

|

C236-1

|

|

C236-6

|

|

C236-2

|

|

C236-3

|

|

C236-2

|

|

C236-4

|

|

C236-2

|

|

C236-6

|

|

C236-3

|

|

C236-4

|

|

C236-3

|

|

C236-6

|

|

C236-4

|

|

C236-6

|

Are the resistances greater than 10,000 ohms?

| Yes

|

INSTALL a new air distribution blend door actuator,

REFER to:

Air Distribution Door Actuator

(412-00 Climate Control System - General Information, Removal and Installation).

TEST the system for normal operation. If the concern is still present, GO to

E5

|

|

| E5

CHECK FOR CORRECT FCIM (FRONT CONTROLS INTERFACE MODULE)

OPERATION

|

-

Disconnect and inspect all the

connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Connect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

For vehicles equipped with Sony® Audio System,

REFER to:

Front Controls Interface Module (FCIM)

(415-00C Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Sony Audio System, Removal and Installation).

For vehicles equipped with Touchscreen Display,

REFER to:

Front Controls Interface Module (FCIM)

(415-00B Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Touchscreen Display, Removal and Installation).

For all other audio systems,

REFER to:

Front Controls Interface Module (FCIM)

(415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. ADDRESS

the root cause of any connector or pin issues.

|

|

Insufficient, Erratic Or No Heat

Normal Operation and Fault Conditions

When the engine is at operating temperature hot coolant flows from the electric motor through the heater core and back to

the electric motor. Correct coolant temperatures are critical for good heater performance.

Possible Sources

-

Wiring, terminals or connectors

-

Temperature blend door actuator(s)

-

Heater core

Visual Inspection and Diagnostic Pre-checks

-

Inspect for low engine coolant level.

PINPOINT TEST F : INSUFFICIENT, ERRATIC OR NO HEAT

| F1

CHECK FOR CORRECT ENGINE COOLANT LEVEL

|

-

Check the engine coolant level.

Is the engine coolant at the correct level as indicated on the engine coolant recovery reservoir?

|

| F2

CHECK THE ENGINE COOLING SYSTEM FOR LEAKS

|

-

Pressure test the cooling system for leaks.

-

For 1.5L engine,

REFER to:

Engine Cooling

(303-03A Engine Cooling - 1.5L EcoBoost (118kW/160PS), Diagnosis and Testing).

-

For 1.6L engine,

REFER to:

Engine Cooling

(303-03B Engine Cooling - 1.6L EcoBoost (132kW/180PS) - Sigma, Diagnosis and Testing).

-

For 2.0L engine,

REFER to:

Engine Cooling

(303-03C Engine Cooling - 2.0L EcoBoost (184kW/250PS) - MI4, Diagnosis and Testing).

-

For 2.5L engine,

REFER to:

Engine Cooling

(303-03D Engine Cooling - 2.5L Duratec (125kW/170PS), Diagnosis and Testing).

Does the engine cooling system leak?

| Yes

|

REPAIR the engine coolant leak. TEST the system for normal operation.

|

|

| F3

CHECK FOR COOLANT FLOW TO THE HEATER CORE

|

-

Run the motor until it reaches normal operating temperature. Select the floor position on the control assembly. Set the temperature

control to full warm and the blower to the lowest setting.

-

Using a suitable temperature measuring device, check the heater core inlet hose to see if it is hot.

Is the heater core inlet hose hot?

| No

|

For 1.5L engine,

REFER to:

Engine Cooling

(303-03A Engine Cooling - 1.5L EcoBoost (118kW/160PS), Diagnosis and Testing).

For 1.6L engine,

REFER to:

Engine Cooling

(303-03B Engine Cooling - 1.6L EcoBoost (132kW/180PS) - Sigma, Diagnosis and Testing).

For 2.0L engine,

REFER to:

Engine Cooling

(303-03C Engine Cooling - 2.0L EcoBoost (184kW/250PS) - MI4, Diagnosis and Testing).

For 2.5L engine,

REFER to:

Engine Cooling

(303-03D Engine Cooling - 2.5L Duratec (125kW/170PS), Diagnosis and Testing).

|

|

| F4

CHECK FOR A PLUGGED OR RESTRICTED HEATER CORE

|

-

Using a suitable temperature measuring device, measure the heater core outlet hose temperature.

Is the heater core outlet hose temperature similar to the inlet hose temperature (within approximately 6-17°C [10-30°F])?

| No

|

INSTALL a new heater core.

REFER to:

Heater Core

(412-00 Climate Control System - General Information, Removal and Installation).

|

|

The

Is Inoperative

Refer to Wiring Diagrams Cell 55 for schematic and connector information.

Normal Operation and Fault Conditions

Control System Logic

REFER to:

Climate Control System - Vehicles With: Dual Automatic Temperature Control (DATC) - System Operation and Component Description

(412-00 Climate Control System - General Information, Description and Operation).

Possible Sources

-

Wiring, terminals or connectors

-

pressure transducer

-

Evaporator temperature sensor

-

-

-

Electric cooling fan

-

Active grille shutters

Visual Inspection and Diagnostic Pre-checks

PINPOINT TEST G : THE A/C (AIR CONDITIONING)

IS INOPERATIVE

| NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

|

| G1

CHECK FOR DIAGNOSTIC TROUBLE CODES (DTCS)

|

-

Using a diagnostic scan tool, Clear all Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, retrieve all Continuous Memory Diagnostic Trouble Codes (CMDTCs).

Are there any climate control related Diagnostic Trouble Codes (DTCs)?

| Yes

|

REFER to

charts in this section.

|

|

| G2

ELECTRIC COOLING FAN FUNCTIONAL CHECK

|

-

Using a diagnostic scan tool, carry out the

self-test.

Does the electric cooling fan operate sometime during the

self-test?

| No

|

DIAGNOSE the electric cooling fan operation. REFER to Powertrain Control/Emissions Diagnosis (PC/ED) manual. Section 3 Symptom

Charts.

|

|

| G3

VERIFY THE GRILLE SHUTTER OPERATION USING THE PCM (POWERTRAIN CONTROL MODULE)

GRILL SHUTTER A POSITION - COMMANDED (GRILL_A_CMD) PID (PARAMETER IDENTIFICATION)

|

-

Start the engine and allow it to idle for at least 30 seconds to allow for the grille shutter calibration to complete.

-

Using a diagnostic scan tool, view

.

-

Using a diagnostic scan tool, select the

GRILL_A_CMD and command the grille shutter from 100% (open) to 0% (closed) while observing the grille shutter operation from

the front of the vehicle.

Does the grill shutter fully open and close when commanded by the scan tool?

| No

|

DIAGNOSE the active grille shutter is inoperative or does not operate correctly.

REFER to:

Active Grille Shutter

(501-02 Front End Body Panels, Diagnosis and Testing).

|

|

| G4

CHECK THE A/C (AIR CONDITIONING)

SYSTEM PRESSURE

|

-

With the R-134a manifold gauge set connected, check the

system pressure.

Is the

system pressure above 290 kPa (42 psi)?

|

| G5

CHECK THE PCM (POWERTRAIN CONTROL MODULE)

A/C (AIR CONDITIONING)

PRESSURE SENSOR (ACP_PRESS) PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

-

With a manifold gauge set connected, compare the pressure readings of the manifold gauge set and the

ACP_PRESS

.

Are the pressure values of the manifold gauge set and the ACP_PRESS

similar?

|

| G6

COMPARE THE EVAPORATOR TEMPERATURE SENSOR TO THE PCM (POWERTRAIN CONTROL MODULE)

AMBIENT AIR TEMPERATURE (AAT) PID (PARAMETER IDENTIFICATION)

|

-

Allow the vehicle exterior and interior to stabilize to ambient temperature.

-

Disconnect Evaporator Temperature Sensor C296

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|

C296-1 (component side)

C296-1 (component side)

|

|

C296-2 (component side)

C296-2 (component side)

|

-

Compare the resistance values to the table below:

|

Ambient Temperature

°F (

°C)

|

Resistance

|

|

-4.0

°F (

-20

°C)

|

263,111-290,807 ohms

|

|

32.0

°F (

°C)

|

91,058-100,644 ohms

|

|

68.0

°F (

20

°C)

|

35,473-39,207 ohms

|

|

77.0

°F (

25

°C)

|

28,500-31,500 ohms

|

|

103.9

°F (

40

°C)

|

15,307-16,919 ohms

|

|

139.9

°F (

60

°C)

|

7,171-7,925 ohms

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

Are the temperature values similar?

| No

|

INSTALL a new evaporator temperature sensor.

REFER to:

Evaporator Temperature Sensor

(412-00 Climate Control System - General Information, Removal and Installation).

|

|

| G7

CHECK THE FCIM (FRONT CONTROLS INTERFACE MODULE)

A/C (AIR CONDITIONING)

SWITCH (CC_SW_AC) PID (PARAMETER IDENTIFICATION)

WITH THE A/C (AIR CONDITIONING)

ON

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

Does the

display ON?

|

| G8

CHECK THE PCM (POWERTRAIN CONTROL MODULE)

AIR CONDITIONING COMPRESSOR COMMANDED STATE (ACC_CMD) PID (PARAMETER IDENTIFICATION)

WITH THE A/C (AIR CONDITIONING)

ON

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

Does the

display ON?

|

| G9

CHECK FOR CORRECT FCIM (FRONT CONTROLS INTERFACE MODULE)

OPERATION

|

-

Disconnect and inspect all the

connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Connect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

For vehicles equipped with Sony® Audio System,

REFER to:

Front Controls Interface Module (FCIM)

(415-00C Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Sony Audio System, Removal and Installation).

For vehicles equipped with Touchscreen Display,

REFER to:

Front Controls Interface Module (FCIM)

(415-00B Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Touchscreen Display, Removal and Installation).

For all other audio systems,

REFER to:

Front Controls Interface Module (FCIM)

(415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. ADDRESS

the root cause of any connector or pin issues.

|

|

| G10

CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect the

connectors.

-

Repair:

-

corrosion (replace connector or terminals – clean module pins)

-

damaged or bent pins – replace terminals/pins

-

pushed-out pins – replace pins as necessary

-

Connect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and verify the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

For 1.5L,

REFER to:

Powertrain Control Module (PCM)

(303-14A Electronic Engine Controls - 1.5L EcoBoost (118kW/160PS), Removal and Installation).

For 1.6L,

REFER to:

Powertrain Control Module (PCM)

(303-14B Electronic Engine Controls - 1.6L EcoBoost (132kW/180PS) - Sigma, Removal and Installation).

For 2.0L,

REFER to:

Powertrain Control Module (PCM)

(303-14C Electronic Engine Controls - 2.0L EcoBoost (184kW/250PS) - MI4, Removal and Installation).

For 2.5L,

REFER to:

Powertrain Control Module (PCM)

(303-14D Electronic Engine Controls - 2.5L Duratec (125kW/170PS), Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

The

Is Always On -

Mode Always Commanded On

Refer to Wiring Diagrams Cell 55 for schematic and connector information.

Normal Operation and Fault Conditions

Control System Logic

REFER to:

Climate Control System - Vehicles With: Dual Automatic Temperature Control (DATC) - System Operation and Component Description

(412-00 Climate Control System - General Information, Description and Operation).

Possible Sources

-

Wiring, terminals or connectors

-

-

PINPOINT TEST H : THE A/C (AIR CONDITIONING)

IS ALWAYS ON - A/C (AIR CONDITIONING)

MODE ALWAYS COMMANDED ON

| NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

|

| H1

INSPECT THE CABIN AIR FILTER

|

-

Inspect the cabin air filter,

REFER to:

Cabin Air Filter

(412-00 Climate Control System - General Information, Removal and Installation).

Is the cabin air filter OK?

| Yes

|

If

P1464

is

present, GO to

H2

If

P1464

is not

present, GO to

H3

|

| No

|

INSTALL a new cabin air filter.

|

|

| H2

RETEST FOR PCM (POWERTRAIN CONTROL MODULE)

DIAGNOSTIC TROUBLE CODES (DTCS)

|

|

NOTE:

If the

selector is not in the OFF position during the self-test, the

falsely sets

P1464.

-

Place the

selector in the OFF position.

-

Using a diagnostic scan tool, carry out the

self-test.

-

Record all

Diagnostic Trouble Codes (DTCs).

-

Using a diagnostic scan tool, carry out the

self-test.

Does

P1464 return?

| No

|

The concern was most likely caused by the

selector not set in the OFF position during the self-test. DIAGNOSE all other climate control related Diagnostic Trouble

Codes (DTCs) and symptoms.

For all other climate control related

Diagnostic Trouble Codes (DTCs), GO to

H3

|

|

| H3

CHECK THE FCIM (FRONT CONTROLS INTERFACE MODULE)

A/C (AIR CONDITIONING)

SWITCH STATUS (CC_SW_AC) PID (PARAMETER IDENTIFICATION)

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

-

Select panel mode, press and release the

button (indicator off) on the

controls.

Does the

display Active when pressed and Inactive when released?

|

| H4

CHECK THE PCM (POWERTRAIN CONTROL MODULE)

A/C (AIR CONDITIONING)

REQUEST SIGNAL (AC_REQ) PID (PARAMETER IDENTIFICATION)

WITH THE A/C (AIR CONDITIONING)

OFF

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

-

While in panel mode, release the

button (indicator off) on the

controls.

Does the

display off?

|

| H5

CHECK THE PCM (POWERTRAIN CONTROL MODULE)

A/C (AIR CONDITIONING)

REQUEST SIGNAL (AC_REQ) PID (PARAMETER IDENTIFICATION)

WITH FCIM (FRONT CONTROLS INTERFACE MODULE)

DISCONNECTED

|

-

Using a diagnostic scan tool, view

Parameter Identifications (PIDs).

Does the

display off?

|

| H6

CHECK FOR CORRECT FCIM (FRONT CONTROLS INTERFACE MODULE)

OPERATION

|

-

Disconnect and inspect all the

connectors.

-

Repair:

-

corrosion (install new connector or terminals – clean module pins)

-

damaged or bent pins – install new terminals/pins

-

pushed-out pins – install new pins as necessary

-

Connect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and determine if the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

For vehicles equipped with Sony® Audio System,

REFER to:

Front Controls Interface Module (FCIM)

(415-00C Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Sony Audio System, Removal and Installation).

For vehicles equipped with Touchscreen Display,

REFER to:

Front Controls Interface Module (FCIM)

(415-00B Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC/Touchscreen Display, Removal and Installation).

For all other audio systems,

REFER to:

Front Controls Interface Module (FCIM)

(415-00A Information and Entertainment System - General Information - Vehicles With: AM/FM/CD/SYNC, Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by a loose or corroded connector. ADDRESS

the root cause of any connector or pin issues.

|

|

| H7

CHECK FOR CORRECT PCM (POWERTRAIN CONTROL MODULE)

OPERATION

|

-

Disconnect and inspect the

connectors.

-

Repair:

-

corrosion (replace connector or terminals – clean module pins)

-

damaged or bent pins – replace terminals/pins

-

pushed-out pins – replace pins as necessary

-

Connect the

connectors. Make sure they seat and latch correctly.

-

Operate the system and verify the concern is still present.

Is the concern still present?

| Yes

|

CHECK

for any applicable Technical Service Bulletins (TSBs). If a

exists for this concern, DISCONTINUE this test and FOLLOW

instructions. If no Technical Service Bulletins (TSBs) address this concern, INSTALL a new

.

For 1.5L,

REFER to:

Powertrain Control Module (PCM)

(303-14A Electronic Engine Controls - 1.5L EcoBoost (118kW/160PS), Removal and Installation).

For 1.6L,

REFER to:

Powertrain Control Module (PCM)

(303-14B Electronic Engine Controls - 1.6L EcoBoost (132kW/180PS) - Sigma, Removal and Installation).

For 2.0L,

REFER to:

Powertrain Control Module (PCM)

(303-14C Electronic Engine Controls - 2.0L EcoBoost (184kW/250PS) - MI4, Removal and Installation).

For 2.5L,

REFER to:

Powertrain Control Module (PCM)

(303-14D Electronic Engine Controls - 2.5L Duratec (125kW/170PS), Removal and Installation).

|

| No

|

The system is operating correctly at this time. The concern may have been caused by module connections. ADDRESS the root cause

of any connector or pin issues.

|

|

The Temperature Control Is Inoperative Or Does Not Operate Correctly - Driver Side

Refer to Wiring Diagrams Cell 55 for schematic and connector information.

Normal Operation and Fault Conditions

Temperature Door Actuator - Driver side,

REFER to:

Climate Control System - Vehicles With: Dual Automatic Temperature Control (DATC) - System Operation and Component Description

(412-00 Climate Control System - General Information, Description and Operation).

During an actuator calibration cycle, the module drives the temperature door until the door reaches both internal stops in

the

case. If the temperature door is temporarily obstructed or binding during a calibration cycle, the module may interpret this

as the actual end of travel for the door. When this condition occurs and the module commands the actuator to its end of travel,

the airflow may not be the expected temperature.

DTC Fault Trigger Conditions

|

DTC

|

Description

|

Fault Trigger Conditions

|

|

B1081:11

|

Left Temperature Damper Motor: Circuit Short To Ground

|

This

sets when the module senses lower the expected voltage on an actuator motor circuit when voltage is applied to drive the

motor, indicating a short to ground. The motor can move only in one direction.

|

|

B1081:12

|

Left Temperature Damper Motor: Circuit Short To Battery

|

This

sets when the module senses higher than expected voltage on the actuator motor circuit when ground is applied to drive the

motor, indicating a short to voltage. The motor can move only in one direction.

|

|

B1081:13

|

Left Temperature Damper Motor: Open Circuit

|

This

sets when the module senses no voltage on the actuator motor circuit when ground is applied to drive the motor, indicating

a open circuit. The motor can not move.

|

|

B11E5:11

|

Left HVAC Damper Position Sensor: Circuit Short to Ground

|

This

sets when the module senses less than 1 volt on the actuator feedback circuit, indicating a short to ground.

|

|

B11E5:15

|

Left HVAC Damper Position Sensor: Circuit Short to Battery or Open

|

This

sets when the module senses greater than 4 volts on the actuator feedback circuit, indicating an open circuit or a short

to voltage.

|

Possible Sources

-

Wiring, terminals or connectors

-

Driver side temperature door actuator

-

PINPOINT TEST I : THE TEMPERATURE CONTROL IS INOPERATIVE OR DOES NOT OPERATE CORRECTLY - DRIVER SIDE

| NOTICE:

Use the correct probe adapter(s) when making measurements. Failure to use the correct probe adapter(s) may damage the connector.

|

| I1

CHECK THE DRIVER SIDE TEMPERATURE DOOR ACTUATOR CIRCUITS FOR A SHORT TO VOLTAGE

|

-

Disconnect Driver side temperature door actuator C2091

.

-

Measure:

|

Positive Lead

|

Measurement / Action

|

Negative Lead

|